Turbine Repairs

Downtime Management

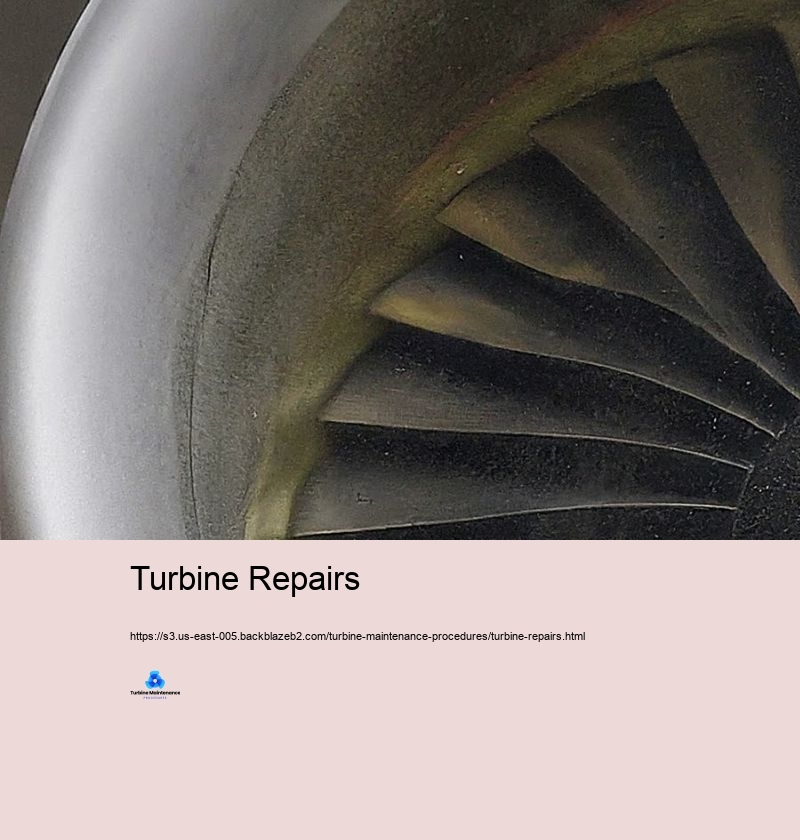

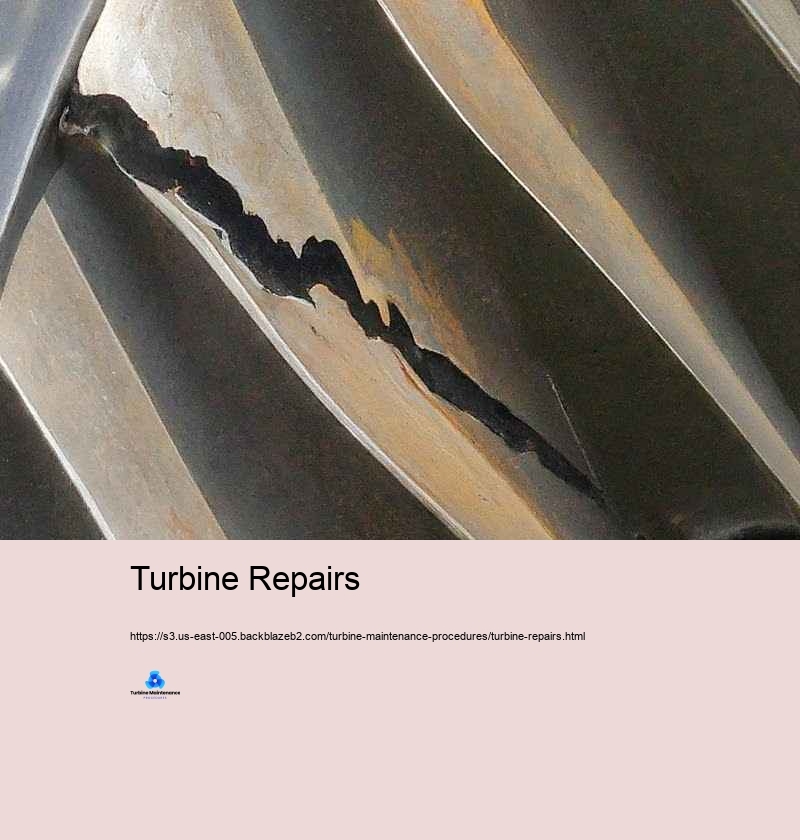

Turbine maintenance is an important aspect of power generation, industrial processes, and various various other applications where generators play a necessary function. Proper maintenance warranties ideal efficiency, extends the life expectancy of the devices, and safeguards against expensive failings. This intro to turbine maintenance checks out the key principles and practices needed for preserving these detailed makers effectively. At its core, turbine maintenance relates to keeping the honesty and efficiency of the turbine system. Wind turbines, whether heavy steam, gas, or hydraulic, are ingenious pieces of equipment that convert power from a liquid (hefty steam, gas, or water) right into mechanical energy. The high-speed rotation, severe temperatures, and stress and anxiety associated with their operation make regular and substantial maintenance necessary. One of the fundamental concepts in turbine maintenance is preventative maintenance. This positive technique consists of routinely set up examinations, cleaning, and small repair work to stop substantial failures prior to they take place. Preventative maintenance typically includes work such as lubricating bearings, checking and transforming clearances, checking blades for wear or damage, and keeping an eye on resonance degrees. By addressing small issues early, preventative maintenance can substantially reduction the threat of devastating failures and broaden the turbine's operational life. Condition-based maintenance is another crucial idea that has in fact gotten value with the development of advanced surveillance modern-day technologies. This approach relies on real-time data from sensing units and checking systems to identify when maintenance is required. Requirements such as resonance, temperature, stress, and oil condition are constantly examined. When these requirements differ normal arrays, it suggests possible concerns that call for rate of interest. Condition-based maintenance makes it possible for a lot more targeted and reputable maintenance tasks, reducing unnecessary downtime and boosting source appropriation. Preparing for maintenance takes condition-based maintenance an action a lot more by utilizing information analytics and artificial intelligence formulas to prepare for when failings are most likely to take place. By assessing historical info and existing operating conditions, expecting maintenance systems can expect feasible troubles prior to they emerge as apparent concerns. This technique allows maintenance teams to mean treatments at one of the most beneficial times, lessening disturbance to procedures and maximizing the performance of maintenance tasks. Turbine Repairs Placement is an important technique in turbine maintenance. Proper alignment of the turbine shaft with the generator or driven tools is essential for smooth operation and long life. Discrepancy can lead to severe resonance, accelerated wear of bearings and seals, and reduced performance. Regular placement checks and modifications, usually utilizing laser placing tools, are a typical part of turbine maintenance routines. Balancing is another vital element of turbine maintenance. The high-speed rotation of turbine aspects suggests that also little inequalities can cause considerable vibration and put on. Dynamic balancing of blades and impellers is done to guarantee smooth operation. This procedure entails consisting of or removing percentages of weight at specific indicate accomplish ideal equilibrium. Normal vibration analysis aids acknowledge inconsistency worries early, making it possible for prompt adjustments. Assessment and cleaning of turbine blades are vital maintenance methods. Blades can struggle with various issues such as fragmentation, deterioration, fouling, or physical problems. Typical analyses, normally utilizing borescopes or numerous other non-destructive screening methods, assistance identify these problems. Cleansing of blades, which may consist of chemical cleansing or mechanical approaches like grit blasting, assists preserve wind resistant efficiency and protects against performance destruction. Lubrication administration is a crucial facet of turbine maintenance. Appropriate lubrication of bearings, devices, and different other transferring elements is necessary for reducing friction and put on. This includes not only ensuring an adequate supply of lubing material yet also inspecting its top quality. Oil evaluation is a common practice that assists detect contaminants, use pieces, and adjustments in oil household or commercial residential properties that could suggest establishing problems in the turbine system. Seal maintenance is another important method. Seals stop leak of working liquids and lubes, and their failure can cause substantial efficiency losses and feasible safety and protection dangers. Routine assessment and substitute of seals, specifically in high-pressure or high-temperature locations, is a standard component of turbine maintenance regimens. Control system maintenance is considerably important as wind turbines become much more digital and digitally regulated. This requires routine checks and calibration of picking up units, actuators, and control shutoffs. Software program application updates and cybersecurity steps are additionally essential facets of modern turbine control system maintenance. Safety is vital in all turbine maintenance tasks. Wind turbines entail high powers, extreme temperature levels, and possibly unsafe products. Stringent adherence to security procedures, including lockout/tagout procedures, constrained space gain access to procedures, and right use specific security devices (PPE), is essential. Safety and security training and routine correspondence course for maintenance workers are crucial techniques in turbine maintenance programs. Documents and record-keeping are necessary methods in turbine maintenance. Comprehensive logs of all maintenance activities, including analyses, repair work, and component substitutes, supply essential historical information for fad analysis and future maintenance prep work. Several organizations now utilize digital maintenance management systems (CMMS) to simplify this procedure and help in data evaluation. Training and ability growth of maintenance workers is a recurring method in turbine maintenance. As turbine innovations develop, maintenance techniques and tools in addition advancement. Normal training programs ensure that maintenance staff are up-to-date with one of the most current maintenance strategies, diagnostic gadgets, and safety and safety and security procedures. Environmental aspects to think about are ending up being progressively important in turbine maintenance. This contains appropriate taking care of and disposal of hazardous products like used oils and cleaning up chemicals. Great deals of maintenance practices currently concentrate on reducing environmental influence while ensuring optimal turbine performance. Turbine maintenance is a center and varied area that combines mechanical, electric, and considerably, electronic efficiency. The crucial ideas of preventive, condition-based, and anticipating maintenance develop the structure of contemporary turbine maintenance approaches. Practices such as placement, harmonizing, blade evaluation and cleansing, lubrication keeping track of, and control system maintenance are important for guaranteeing the reliability, performance, and durability of turbine systems. As turbine advancements continue to advance, maintenance practices will absolutely furthermore advancement, consisting of brand-new developments and techniques to meet the difficulties of keeping these crucial pieces of equipment in an ever-changing power landscape.

Turbine Repairs