Bearing Inspection

Compressor Blades

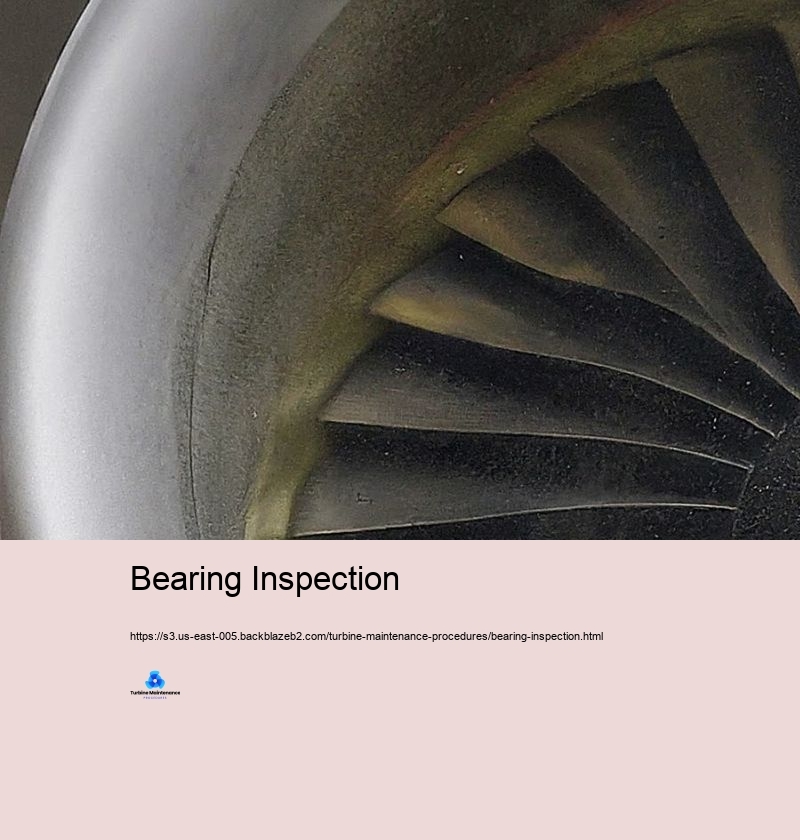

Turbine maintenance is an essential facet of power generation, commercial processes, and numerous various other applications where generators play an important function. Correct maintenance assurances maximum efficiency, expands the life-span of the devices, and stays clear of pricey malfunctions. This intro to turbine maintenance checks out the important principles and techniques necessary for protecting these complex gadgets effectively. At its core, turbine maintenance relates to preserving the stability and performance of the turbine system. Generators, whether vapor, gas, or hydraulic, are ingenious pieces of machinery that transform power from a liquid (hefty steam, gas, or water) right into power. The high-speed rotation, extreme temperature degrees, and anxiety involved in their procedure make typical and comprehensive maintenance essential. One of the essential ideas in turbine maintenance is precautionary maintenance. This positive technique consists of frequently scheduled analyses, cleansing, and minor repair work solutions to prevent significant failings before they happen. Preventative maintenance usually consists of tasks such as lubricating bearings, checking and readjusting clearances, examining blades for wear or damages, and tracking vibration degrees. By addressing small problems early, preventative maintenance can dramatically decrease the danger of catastrophic failures and expand the turbine's practical life. Condition-based maintenance is another vital principle that has obtained value with the arrival of sophisticated keeping track of advancements. This technique relies upon real-time data from sensing units and inspecting systems to establish when maintenance is important. Specifications such as resonance, temperature level, pressure, and oil problem are constantly monitored. When these parameters differ normal varieties, it programs possible concerns that require focus. Condition-based maintenance makes it possible for a lot more targeted and reliable maintenance tasks, decreasing unwanted downtime and enhancing source part. Predictive maintenance takes condition-based maintenance an activity much more by utilizing data analytics and expert system solutions to projection when failures are likely to happen. By evaluating historical information and present running problems, expecting maintenance systems can forecast feasible issues before they appear as visible issues. This technique licenses maintenance groups to mean interventions at one of one of the most ideal times, lessening disturbance to operations and maximizing the efficiency of maintenance tasks. Placing is a crucial method in turbine maintenance. Appropriate placing of the turbine shaft with the generator or driven devices is vital for smooth procedure and longevity. Imbalance can cause excessive vibration, boosted wear of bearings and seals, and decreased performance. Typical positioning checks and changes, usually making use of laser placing devices, are a fundamental element of turbine maintenance routines. Balancing is another essential component of turbine maintenance. The high-speed turning of turbine components methods that also tiny discrepancies can cause significant resonance and wear. Dynamic balancing of blades and impellers is executed to guarantee smooth procedure. This process includes including or removing percents of weight at information indicate accomplish excellent equilibrium. Routine resonance analysis aids determine disparity problems early, permitting timely modifications. Assessment and cleansing of turbine blades are crucial maintenance methods. Compressor Blades Blades can experience various troubles such as fragmentation, rust, fouling, or physical damage. Regular assessments, often making use of borescopes or different other non-destructive testing strategies, aid recognize these troubles. Cleansing of blades, which may consist of chemical cleansing or mechanical strategies like grit blasting, aids protect wind resistant effectiveness and protects against efficiency wear and tear. Lubrication management is a critical element of turbine maintenance. Correct lubrication of bearings, gears, and numerous other moving parts is needed for lowering rubbing and use. This entails not simply ensuring an appropriate supply of lube yet also examining its top quality. Oil evaluation is a typical method that helps discover impurities, use little bits, and adjustments in oil residential or business properties that could recommend establishing troubles in the turbine system. Seal maintenance is one more necessary technique. Seals safeguard versus leak of working fluids and lubricating compounds, and their failing can result in substantial performance losses and prospective safety risks. Routine evaluation and alternative of seals, especially in high-pressure or high-temperature locations, is a fundamental component of turbine maintenance routines. Control system maintenance is gradually necessary as wind turbines happened a lot more automated and online handled. This includes routine checks and calibration of sensing systems, actuators, and control shutoffs. Software updates and cybersecurity steps are likewise essential elements of contemporary turbine control system maintenance. Safety is very important in all turbine maintenance tasks. Wind turbines consist of high powers, serious temperatures, and potentially dangerous items. Bearing Inspection Rigorous adherence to safety and security and protection procedures, containing lockout/tagout procedures, constrained space entryway procedures, and suitable use personal safety devices (PPE), is essential. Safety training and routine document program for maintenance workers are important practices in turbine maintenance programs. Documents and record-keeping are vital practices in turbine maintenance. Comprehensive logs of all maintenance tasks, containing examinations, fixings, and part alternatives, give essential historical details for trend analysis and future maintenance intending. A number of organizations now use electronic maintenance monitoring systems (CMMS) to boost this treatment and advertise information evaluation. Training and ability growth of maintenance workers is a continuous technique in turbine maintenance. As turbine modern technologies advancement, maintenance techniques and gadgets in addition advancement. Regular training programs make certain that maintenance group are current with the present maintenance techniques, evaluation devices, and security and protection procedures. Ecological factors to consider are winding up being significantly important in turbine maintenance. This includes ideal taking care of and disposal of unsafe materials like utilized oils and cleaning chemicals. Lots of maintenance techniques presently focus on decreasing environmental impact while ensuring optimum turbine efficiency. Turbine maintenance is a complex and diverse location that includes mechanical, electrical, and significantly, electronic know-how. The essential concepts of preventive, condition-based, and anticipating maintenance develop the framework of modern turbine maintenance techniques. Practices such as positioning, harmonizing, blade assessment and cleaning, lubrication monitoring, and control system maintenance are essential for guaranteeing the stability, efficiency, and longevity of turbine systems. As turbine developments continue to establish, maintenance methods will similarly development, including brand-new technologies and techniques to fulfill the difficulties of preserving these vital devices in an ever-changing energy landscape.