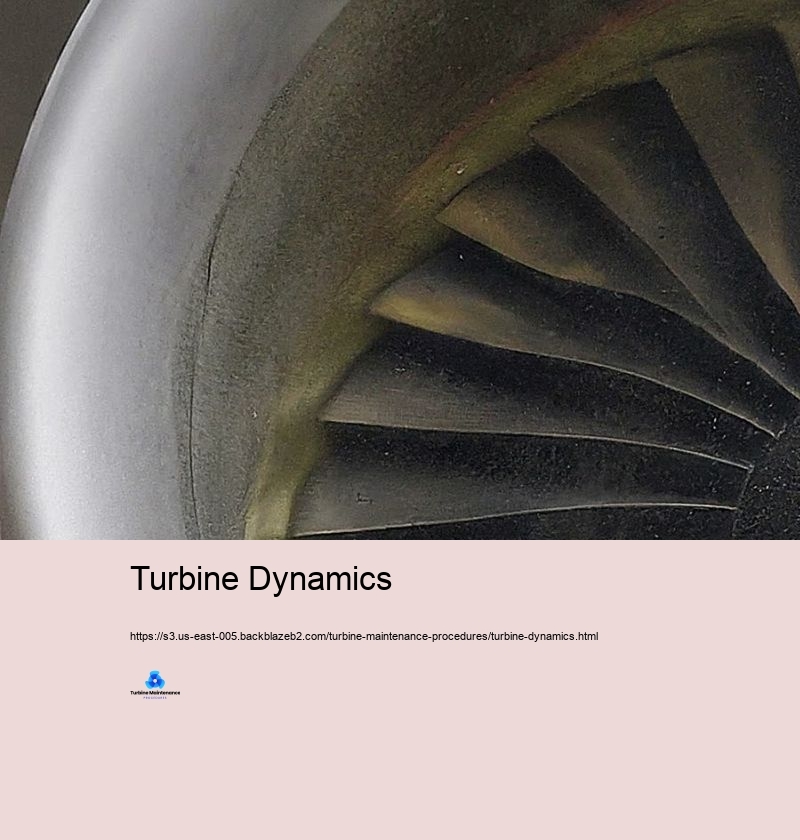

Executing a turbine overhaul and component replacement includes a comprehensive approach that makes certain the long-lasting effectiveness, integrity, and security of turbine procedures. Turbines, whether used in power generation, air travel, or commercial applications, are challenging tools that run under high-stress conditions. In time, elements can break, causing lowered effectiveness and prospective failings. Executing finest methods during overhauls and element substitutes is vital for keeping optimal turbine function and increasing its operational life. Here an extensive consider the best strategies for turbine overhaul and component substitute. The primary step in an effective turbine overhaul is thorough preparing and scheduling. This entails a comprehensive assessment of the turbine's current issue, historic effectiveness information, and any kind of acknowledged problems. By comprehending the specific needs of the turbine, drivers can establish a tailored overhaul plan that resolves all required repair and substitutes. Setting up the overhaul throughout intended downtime or low-demand durations minimizes disruption to procedures and makes certain that the turbine is back online as promptly as practical. Reliable preparation also entails working together with suppliers to make sure that all crucial elements and products are available when needed, securing against hold-ups. A complete examination and evaluation are critical components of the overhaul treatment. This includes uncoupling the turbine and doing a detailed analysis of each component, including blades, blades, bearings, and seals. Advanced analysis gadgets, such as borescopes and non-destructive screening techniques, can be used to establish wear, degeneration, divides, and various other problems that may not show up to the naked eye. By accurately taking a look at the problem of each component, vehicle drivers can establish which components need alternative and which can be replaced or recycled. This detailed examination ensures that all possible problems are settled, reducing the hazard of future failures. When replacing turbine parts, it is needed to utilize high-grade components that satisfy or surpass the preliminary devices provider (OEM) specs. Utilizing substandard components can jeopardize the performance and safety and security of the turbine, resulting in increased maintenance costs and possible failings. Operators should resource replacement parts from reliable suppliers and ensure that they work with the particular turbine design. In many cases, upgrading to more advanced products or styles may be useful, as these can enhance efficiency and expand the life-span of the components. The setup and positioning of turbine parts call for precision and experience. Misalignment or inaccurate setup can cause boosted wear, vibration, and ineffectiveness. It is essential to adhere to OEM standards and take advantage of specialized devices and tools to make certain that components are set up appropriately. This consists of examining clearances, resistances, and torque specifications. Proper placement of turning aspects, such as blades and shafts, is particularly important, as even minor imbalances can create significant practical concerns. By making sure accuracy installment and alignment, operators can maximize turbine performance and minimize the risk of early part stopping working. To enhance the sturdiness and performance of turbine elements, operators can execute innovative treatments and surface area treatments. Thermal barrier surfaces, anti-corrosion finishings, and wear-resistant treatments can shield elements from severe running troubles and prolong their life span. These surfaces are specifically useful for components exposed to warms, such as turbine blades and vanes. By decreasing the results of thermal stress, oxidation, and disintegration, progressed finishings contribute to boosted turbine effectiveness and integrity. After finishing the overhaul and element substitute, extensive screening and validation are vital to warranty that the turbine is running appropriately. This consists of carrying out a collection of examinations, consisting of efficiency tests, vibration assessment, and thermal imaging, to validate that all components are functioning as expected. Operators should certainly additionally check important performance signs, such as performance, outcome, and discharges, to make certain that the turbine fulfills functional criteria. Any type of type of anomalies or inconsistencies from expected performance needs to be taken a look at and addressed quickly. Comprehensive screening and recognition offer guarantee that the overhaul has actually succeeded which the turbine is ready for trusted operation. Preserving extensive records and papers is a finest approach that supports constant turbine maintenance and future overhauls. This contains taping all exam findings, component substitutes, and alterations made throughout the overhaul. Comprehensive documents supply valuable understandings right into the turbine's maintenance background and can inform future maintenance choices. In addition, files of the overhaul procedure, including components taken advantage of and procedures followed, warranties consistency with market standards and regulatory demands. By maintaining precise records, drivers can track the turbine's effectiveness in time and identify trends or reoccuring worries that may demand to be resolved. Acquiring training and ability improvement for maintenance employees is important for reliable turbine overhauls and component substitutes. Operators ought to make certain that their maintenance groups are trained in the most current methods, tools, and technologies made use of in turbine maintenance. This consists of using gain access to to OEM training programs, workshops, and qualification programs. Experienced employees are far better supplied to conduct extensive examinations, do accurate installments, and implement innovative maintenance practices. By cultivating a culture of consistent understanding and improvement, chauffeurs can enhance the efficiency of their maintenance teams and guarantee the resilient honesty of their generators. Lastly, handling a regular enhancement technique is essential for enhancing turbine overhaul and maintenance methods. Operators should seek remarks from maintenance teams, examine performance information, and recognize locations for enhancement. This may entail upgrading maintenance procedures, buying brand-new technologies, or refining training programs. By continuously evaluating and enhancing maintenance techniques, operators can improve turbine efficiency, decrease downtime, and prolong the practical life of their tools.

Finest practices for turbine overhaul and component replacement include a substantial and organized strategy that focuses on preparation, precision, and premium. By performing these techniques, drivers can make certain the integrity, performance, and safety and security of their generators, eventually adding to the success and sustainability of their operations. Via complete emphasis to information and a dedication to high quality, turbine overhauls can be executed effectively, offering lasting advantages and maximizing efficiency sought after settings.