Flow Path Inspections

Electrical Inspections

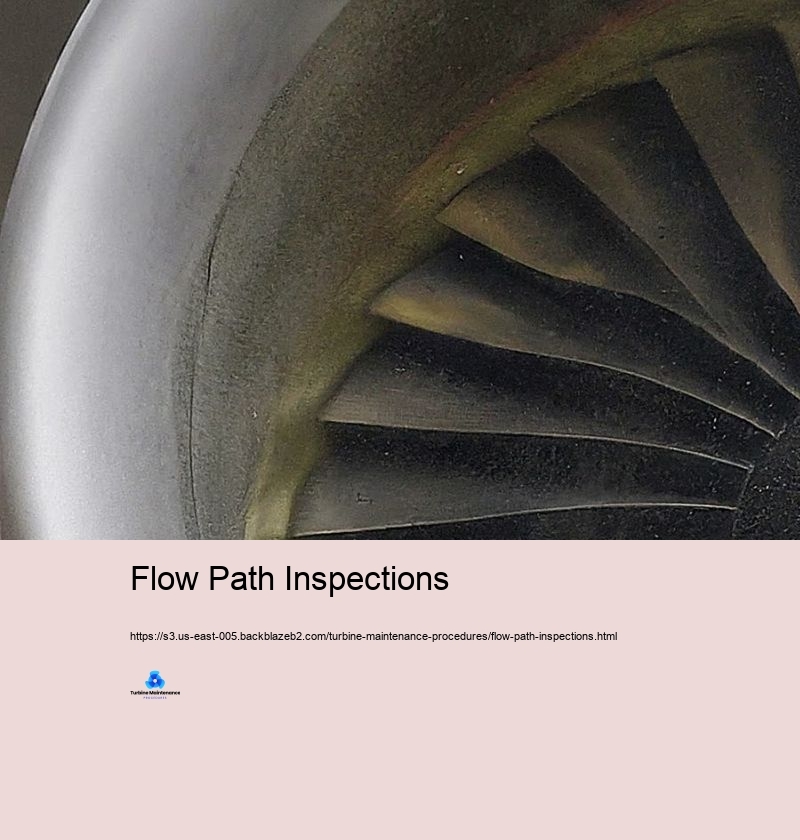

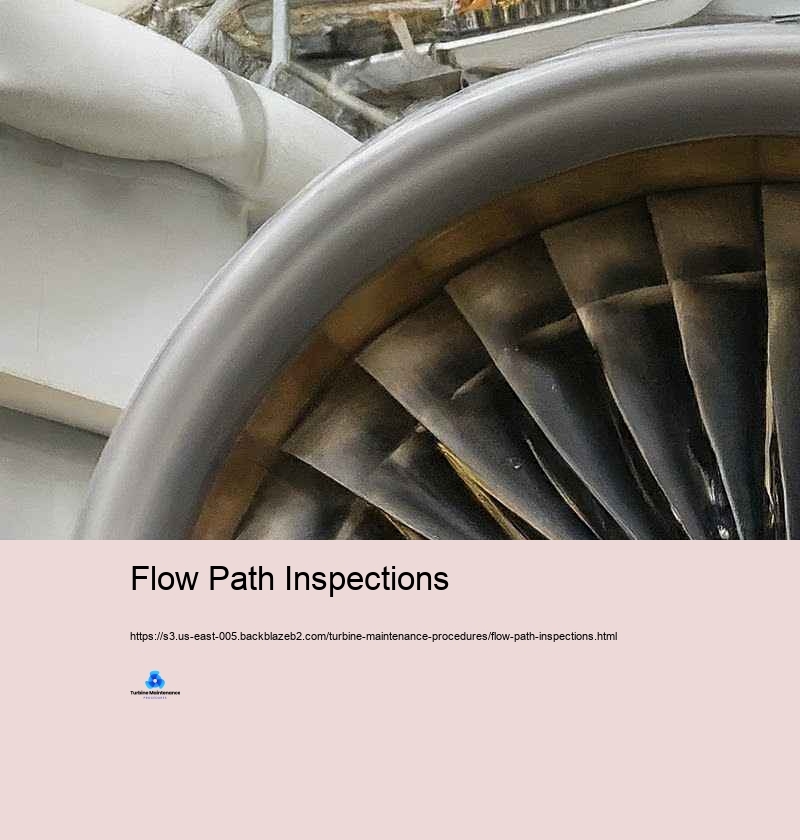

Turbine maintenance is a vital aspect of power generation, commercial processes, and various other applications where generators play a vital task. Correct maintenance warranties maximum efficiency, expands the life expectancy of the tools, and stops costly failings. This introduction to turbine maintenance finds the essential ideas and techniques vital for preserving these complex devices successfully. At its core, turbine maintenance has to do with preserving the stability and effectiveness of the turbine system. Turbines, whether steam, gas, or hydraulic, are innovative products of tools that transform power from a fluid (vapor, gas, or water) into power. The high-speed transforming, extreme temperature levels, and tension related to their treatment make normal and in-depth maintenance vital. One of the basic concepts in turbine maintenance is preventative maintenance. This positive method entails routinely established examinations, cleansing, and small repair work to stay clear of significant failings prior to they happen. Preventative maintenance normally contains work such as lubricating bearings, inspecting and readjusting clearances, reviewing blades for wear or problems, and keeping an eye on vibration degrees. By resolving tiny concerns early, preventative maintenance can considerably minimize the threat of unfortunate failings and extend the turbine's functional life. Condition-based maintenance is one more crucial concept that has acquired importance with the development of innovative surveillance modern technologies. This strategy counts on real-time data from sensing units and keeping an eye on systems to establish when maintenance is required. Criteria such as resonance, temperature level, stress and anxiety, and oil trouble are continuously monitored. When these standards differ normal arrays, it shows possible issues that ask for emphasis. Condition-based maintenance authorizations a lot more targeted and effective maintenance tasks, decreasing unneeded downtime and boosting resource allocation. Predictive maintenance takes condition-based maintenance an action additionally by using info analytics and machine learning algorithms to forecast when failings are most likely to take place. By assessing historic data and present running issues, predictive maintenance systems can forecast prospective issues prior to they appear as visible issues. This strategy makes it possible for maintenance teams to prepare therapies at one of one of the most suitable times, reducing disruption to procedures and making finest use the performance of maintenance activities. Alignment is a necessary method in turbine maintenance. Appropriate placement of the turbine shaft with the generator or driven devices is required for smooth procedure and toughness. Inequality can cause severe vibration, boosted wear of bearings and seals, and minimized performance. Typical placing checks and changes, often making use of laser alignment gadgets, are a conventional part of turbine maintenance programs. Stabilizing is an extra essential aspect of turbine maintenance. The high-speed turning of turbine components indicates that additionally little inequalities can cause significant vibration and use. Dynamic balancing of blades and impellers is implemented to make certain smooth operation. Electrical Inspections This procedure consists of adding or eliminating small amounts of weight at certain points to achieve optimum stability. Regular resonance assessment help identify inequality problems early, allowing timely modifications. Assessment and cleaning of turbine blades are vital maintenance techniques. Blades can manage various problems such as disintegration, rust, fouling, or physical damages. Normal examinations, commonly utilizing borescopes or various other non-destructive screening techniques, help establish these concerns. Cleansing of blades, which might include chemical cleaning or mechanical techniques like grit blasting, aids maintain aerodynamic performance and shields versus performance damage. Lubrication administration is an essential element of turbine maintenance. Appropriate lubrication of bearings, equipments, and other relocating elements is necessary for minimizing friction and use. Flow Path Inspections This includes not simply ensuring an ideal supply of lubricating substance however likewise checking its top quality. Oil analysis is a normal method that helps identify pollutants, use bits, and changes in oil homes that might indicate creating problems in the turbine system. Seal maintenance is one more important strategy. Seals shield versus leak of functioning fluids and lubricating substances, and their falling short can produce substantial performance losses and feasible security and protection threats. Routine inspection and substitute of seals, particularly in high-pressure or high-temperature locations, is a common part of turbine maintenance routines. Control system maintenance is progressively important as generators become far more automated and digitally regulated. This includes normal checks and calibration of sensors, actuators, and control shutoffs. Software application updates and cybersecurity actions are furthermore essential facets of modern turbine control system maintenance. Safety and safety and security is exceptionally essential in all turbine maintenance activities. Generators consist of high powers, serious temperatures, and perhaps hazardous products. Stringent adherence to safety and safety procedures, containing lockout/tagout procedures, confined area entry procedures, and ideal use private safety devices (PPE), is crucial. Security training and normal communication course for maintenance workers are important techniques in turbine maintenance programs. Files and record-keeping are crucial methods in turbine maintenance. Comprehensive logs of all maintenance tasks, containing assessments, dealings with, and part substitutes, provide helpful historic information for pattern analysis and future maintenance prep work. A number of organizations currently utilize digital maintenance management systems (CMMS) to simplify this treatment and advertise information evaluation. Training and skill growth of maintenance workers is a reoccuring method in turbine maintenance. As turbine advancements development, maintenance methods and devices furthermore advance. Normal training programs ensure that maintenance team are up-to-date with the most recent maintenance approaches, analysis devices, and security procedures. Environmental considerations are becoming significantly important in turbine maintenance. This consists of ideal dealing with and disposal of unsafe products like utilized oils and cleaning chemicals. Numerous maintenance approaches currently focus on minimizing eco-friendly impact while ensuring optimum turbine performance. Turbine maintenance is a challenging and multifaceted area that integrates mechanical, electrical, and significantly, electronic competence. The crucial principles of preventive, condition-based, and preparing for maintenance create the structure of modern-day turbine maintenance methods. Practices such as placing, harmonizing, blade analysis and cleaning, lubrication monitoring, and control system maintenance are necessary for guaranteeing the dependability, performance, and long life of turbine systems. As turbine technologies remain to advance, maintenance practices will furthermore advancement, incorporating new modern technologies and methods to accomplish the obstacles of preserving these critical devices in an ever-changing power landscape.