Doing a turbine overhaul and aspect replacement requires a precise technique that assurances the lasting efficiency, dependability, and safety of turbine procedures. Wind turbines, whether made use of in power generation, air travel, or commercial applications, are intricate equipments that operate under high-stress conditions. In time, components can put on, causing decreased performance and prospective failings. Implementing perfect methods throughout overhauls and component replacements is necessary for keeping optimum turbine attribute and prolonging its practical life. Right below a comprehensive take a look at the most reliable strategies for turbine overhaul and part substitute. The very initial step in an efficient turbine overhaul is thorough planning and arranging. This involves a comprehensive analysis of the turbine's present problem, historical efficiency information, and any type of type of known concerns. By acknowledging the certain demands of the turbine, drivers can establish a tailored overhaul approach that attends to all called for repair work services and alternatives. Scheduling the overhaul throughout designated downtime or low-demand durations minimizes disruption to procedures and makes certain that the turbine is back on the web as rapidly as practical. Trustworthy planning furthermore consists of coordinating with suppliers to make sure that all vital parts and items are readily offered when needed, protecting versus hold-ups. A detailed analysis and analysis are crucial elements of the overhaul treatment. This includes taking apart the turbine and performing a thorough analysis of each component, consisting of blades, blades, bearings, and seals. Advanced diagnostic devices, such as borescopes and non-destructive screening methods, can be made use of to figure out wear, rust, splits, and various other defects that might not show up to the nude eye. By precisely checking out the problem of each component, motorists can develop which parts requirement alternative and which can be replaced or recycled. This extensive examination makes certain that all possible concerns are dealt with, reducing the danger of future failures. When transforming turbine parts, it is necessary to take advantage of top-notch components that satisfy or exceed the original devices maker (OEM) specs. Making use of ineffective elements can compromise the performance and security of the turbine, creating improved maintenance prices and possible failings. Operators demands to source alternative elements from credible distributors and make sure that they work with the particular turbine style. In some cases, upgrading to advanced products or designs might be useful, as these can boost performance and prolong the life expectancy of the elements. The installation and placement of turbine elements require precision and proficiency. Imbalance or incorrect installment can produce boosted wear, vibration, and ineffectiveness. It is vital to adhere to OEM standards and use specialized gadgets and equipment to warranty that components are established properly. This consists of checking clearances, tolerances, and torque specs. Appropriate positioning of transforming parts, such as blades and shafts, is especially vital, as also small misalignments can trigger significant operational concerns. By making sure accuracy arrangement and placing, vehicle drivers can enhance turbine efficiency and decline the risk of early part falling short. To improve the long life and performance of turbine parts, operators can accomplish ingenious layers and surface area therapies. Thermal barrier layers, anti-corrosion layers, and wear-resistant therapies can safe components from serious operating conditions and extend their service life. These finishings are specifically beneficial for elements subjected to high temperatures, such as turbine blades and vanes. By minimizing the impacts of thermal stress, oxidation, and fragmentation, advanced surfaces add to improved turbine performance and integrity. After finishing the overhaul and aspect substitute, considerable evaluating and recognition are vital to guarantee that the turbine is running suitably. This entails executing a collection of evaluations, including performance tests, resonance analysis, and thermal imaging, to validate that all parts are functioning as expected. Operators requirements to in addition monitor important effectiveness indications, such as efficiency, outcome, and discharges, to make certain that the turbine satisfies functional needs. Any kind of abnormalities or discrepancies from anticipated performance needs to be checked out and handled immediately. Comprehensive screening and acknowledgment deal assurance that the overhaul has in fact achieved success which the turbine waits for trustworthy procedure. Maintaining in-depth papers and documents is a finest strategy that maintains recurring turbine maintenance and future overhauls. This includes videotaping all examination searchings for, aspect alternatives, and modifications made throughout the overhaul. In-depth documents provide useful understandings right into the turbine's maintenance history and can inform future maintenance decisions. In addition, documentation of the overhaul process, including components utilized and procedures abided by, makes certain compliance with market criteria and regulative demands.

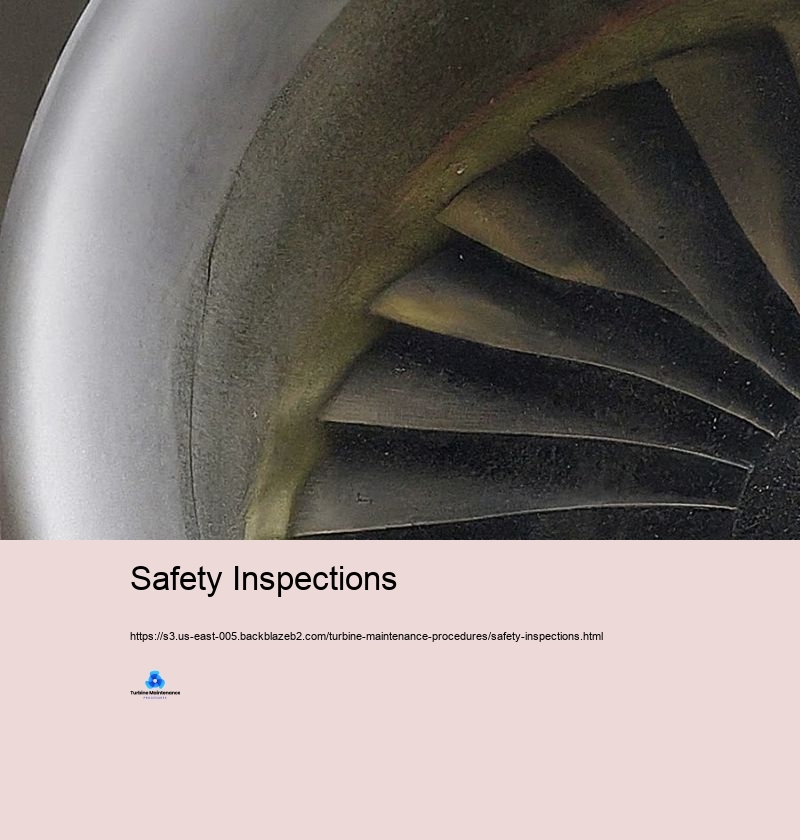

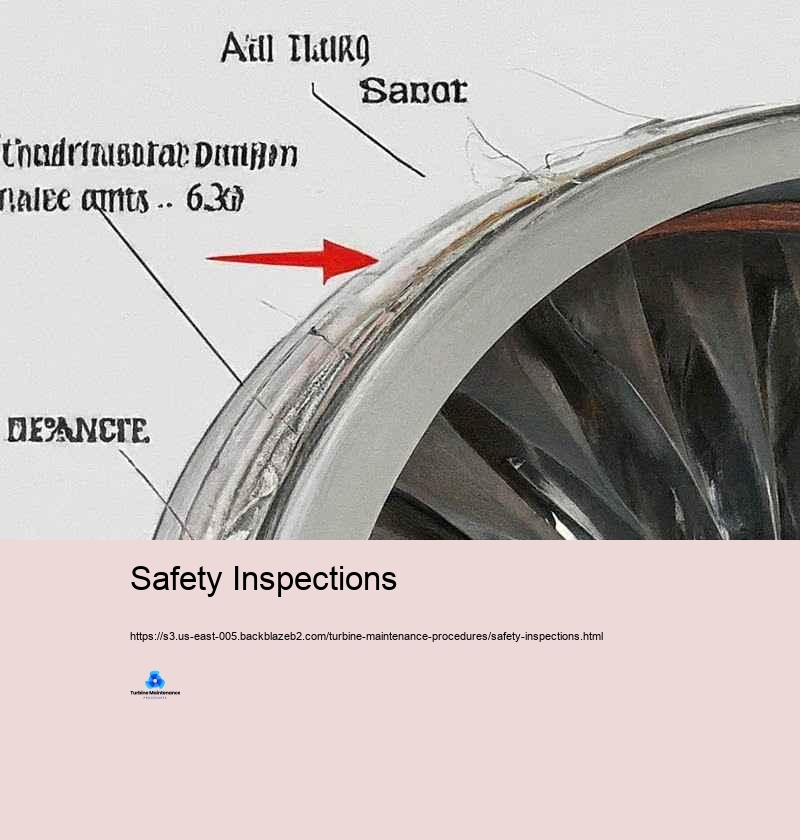

Safety Inspections - Blade Inspection

- Blade Coatings

- Compressor Blades

- Component Replacement

- Turbine Lifespan Analysis

- Data Logging and Analysis

- Blade Erosion

- Downtime Management

By preserving exact files, chauffeurs can track the turbine's performance with time and figure out patterns or reoccuring problems that may need to be addressed. Buying training and skill improvement for maintenance employees is vital for effective turbine overhauls and part replacements. Operators must make certain that their maintenance groups are qualified in the most as much as day methods, tools, and innovations utilized in turbine maintenance. This includes offering availability to OEM training programs, workshops, and certification training programs. Experienced personnel are much better geared up to accomplish extensive exams, do precise installments, and perform innovative maintenance techniques. By promoting a society of constant learning and improvement, drivers can enhance the efficiency of their maintenance teams and make sure the lasting integrity of their wind generators. Finally, taking on a constant enhancement approach is important for enhancing turbine overhaul and maintenance practices. Operators demands to seek comments from maintenance groups, take a look at performance information, and identify locations for enhancement. This could include updating maintenance procedures, investing in brand-new modern innovations, or refining training programs. By continuously examining and enhancing maintenance methods, chauffeurs can boost turbine performance, decrease downtime, and extend the useful life of their gadgets.

Perfect methods for turbine overhaul and part substitute entail a detailed and organized strategy that prioritizes preparation, accuracy, and top quality. By carrying out these methods, motorists can make sure the honesty, efficiency, and safety of their generators, ultimately contributing to the success and sustainability of their procedures. Via careful focus to info and a dedication to top quality, turbine overhauls can be conducted efficiently, offering resilient advantages and maximizing performance prominent environments.