Turbine Overhauls

Performance Testing

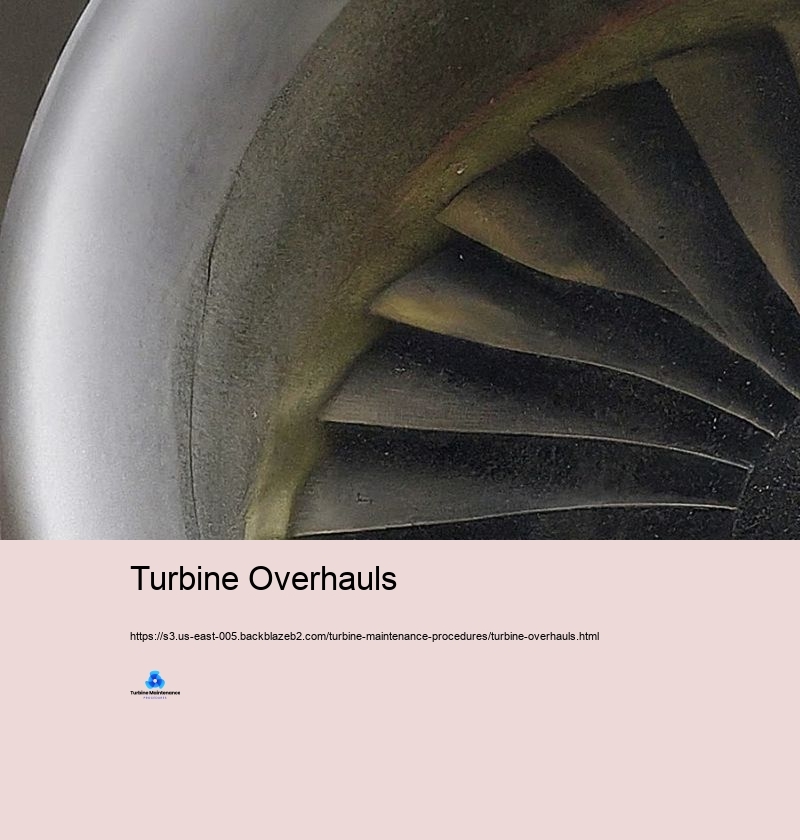

Turbine maintenance is a crucial facet of power generation, commercial processes, and numerous various other applications where wind turbines play a crucial function. Appropriate maintenance sees to it optimal performance, prolongs the life-span of the tools, and quits pricey failures. This introduction to turbine maintenance discovers the important concepts and practices crucial for protecting these complex devices appropriately. At its core, turbine maintenance concerns protecting the sincerity and efficiency of the turbine system. Wind generators, whether vapor, gas, or hydraulic, are advanced items of equipment that change power from a fluid (vapor, gas, or water) right into power. The high-speed rotation, extreme temperatures, and tension associated with their operation make regular and extensive maintenance important. Among the basic ideas in turbine maintenance is preventive maintenance. This aggressive technique includes regularly arranged exams, cleansing, and small mendings to stay clear of major failures prior to they take place. Precautionary maintenance normally includes work such as lubricating bearings, inspecting and adjusting clearances, taking a look at blades for wear or problems, and examining vibration degrees. By managing small problems early, precautionary maintenance can significantly minimize the danger of catastrophic failings and broaden the turbine's useful life. Condition-based maintenance is an added key principle that has actually obtained reputation with the intro of sophisticated tracking modern innovations. This method trusts real-time data from sensing units and checking systems to identify when maintenance is required. Criteria such as vibration, temperature level, pressure, and oil condition are constantly inspected. When these specs differ typical varieties, it suggests feasible issues that call for focus. Condition-based maintenance allows a lot more targeted and reliable maintenance tasks, minimizing unneeded downtime and enhancing resource appropriation. Preparing for maintenance takes condition-based maintenance a step far better by using information analytics and machine learning formulas to predict when failings are more than likely to occur. By assessing historical information and existing running troubles, predictive maintenance systems can prepare for prospective concerns before they materialize as detectable problems. This approach permits maintenance teams to mean interventions at one of the most positive times, reducing disturbance to operations and maximizing the performance of maintenance activities. Placement is an essential technique in turbine maintenance. Proper positioning of the turbine shaft with the generator or driven devices is required for smooth procedure and sturdiness. Discrepancy can cause extreme vibration, quickened wear of bearings and seals, and decreased performance. Regular placement checks and adjustments, often using laser positioning devices, are a typical component of turbine maintenance programs. Balancing is another vital aspect of turbine maintenance. The high-speed rotation of turbine components implies that also tiny inconsistencies can cause significant vibration and use. Dynamic harmonizing of blades and impellers is carried out to ensure smooth treatment. This procedure involves adding or getting rid of percentages of weight at details indicate accomplish maximum equilibrium. Normal resonance analysis help recognize discrepancy issues early, enabling timely modifications. Assessment and cleaning of turbine blades are essential maintenance methods. Blades can experience countless issues such as fragmentation, corrosion, fouling, or physical problems. Routine evaluations, regularly making use of borescopes or various other non-destructive testing methods, assistance determine these concerns. Cleansing of blades, which may require chemical cleansing or mechanical techniques like grit blasting, aids keep wind resistant performance and quits efficiency degeneration. Lubrication checking is an important component of turbine maintenance. Appropriate lubrication of bearings, equipments, and various other transferring parts is vital for lessening friction and put on. This involves not just making certain an adequate supply of lube nonetheless furthermore checking its high quality. Oil evaluation is a normal strategy that aids identify pollutants, put on little bits, and changes in oil buildings that can show creating troubles in the turbine system. Seal maintenance is one more crucial practice. Seals stop leak of functioning liquids and lubricants, and their failure can reason substantial performance losses and potential security and safety risks. Normal evaluation and replacement of seals, specifically in high-pressure or high-temperature areas, is a typical part of turbine maintenance routines. Control system maintenance is increasingly crucial as wind turbines end up being more automated and electronically managed. This consists of typical checks and calibration of sensors, actuators, and control shutoffs. Software application updates and cybersecurity actions are in addition critical elements of contemporary turbine control system maintenance. Safety is extremely crucial in all turbine maintenance activities. Generators consist of high powers, extreme temperature degrees, and possibly dangerous materials. Extensive adherence to security and protection procedures, including lockout/tagout procedures, constricted area accessibility procedures, and appropriate use specific safety devices (PPE), is important. Safety and safety and security training and regular correspondence course for maintenance employees are critical techniques in turbine maintenance programs. Records and record-keeping are essential practices in turbine maintenance. Thorough logs of all maintenance tasks, consisting of evaluations, repair service services, and part replacements, offer important historical information for trend assessment and future maintenance prep work. Many firms currently make use of electronic maintenance management systems (CMMS) to simplify this procedure and assist in information evaluation. Training and ability development of maintenance employees is a constant technique in turbine maintenance. As turbine innovations progress, maintenance methods and devices furthermore advancement. Normal training programs ensure that maintenance group are current with one of the most as much as day maintenance practices, analysis tools, and safety and security procedures. Ecological factors to think about are coming to be progressively crucial in turbine maintenance. This contains correct handling and disposal of damaging products like made use of oils and tidying up chemicals. Turbine Overhauls Lots of maintenance methods now focus on decreasing ecological impact while assuring ideal turbine performance. Turbine maintenance is a center and diverse location that integrates mechanical, electrical, and considerably, electronic efficiency. The essential ideas of precautionary, condition-based, and expecting maintenance produce the structure of contemporary turbine maintenance techniques. Practices such as positioning, integrating, blade analysis and cleaning, lubrication keeping track of, and control system maintenance are critical for ensuring the stability, efficiency, and long life of turbine systems. As turbine technologies continue to progress, maintenance techniques will certainly likewise advance, including brand-new innovations and approaches to satisfy the obstacles of keeping these vital pieces of equipment in an ever-changing energy landscape.