Heat Exchanger Maintenance

System Upgrades

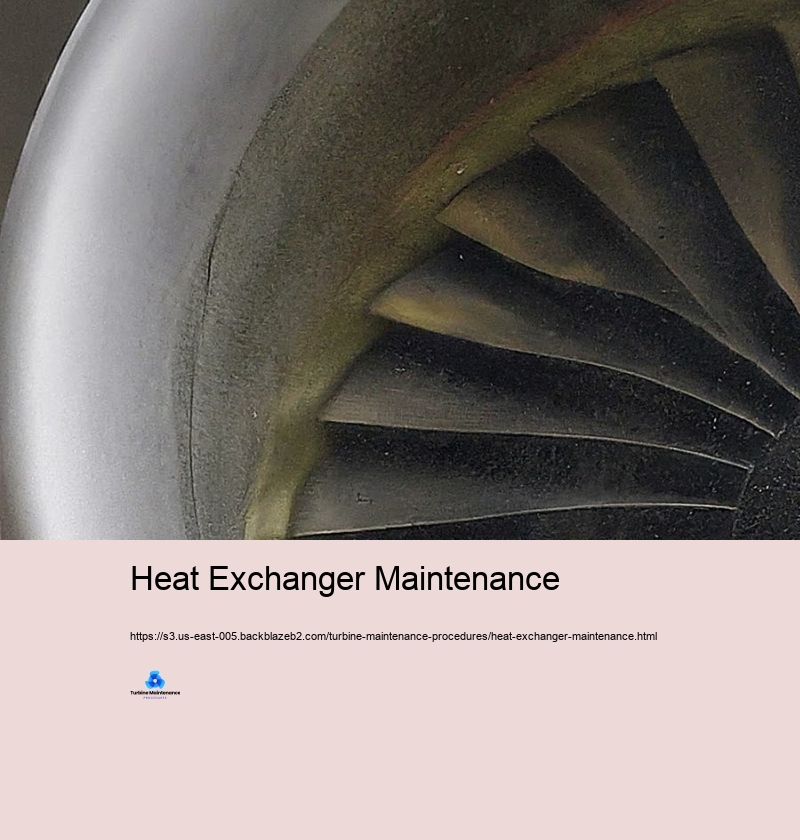

Turbine maintenance is an important facet of power generation, commercial procedures, and various various other applications where wind turbines play a vital obligation. Proper maintenance warranties optimum effectiveness, expands the life-span of the tools, and stops expensive break downs. This introduction to turbine maintenance uncovers the crucial principles and approaches essential for maintaining these complex equipments effectively. At its core, turbine maintenance pertains to protecting the stability and efficiency of the turbine system. Wind generators, whether steam, gas, or hydraulic, are innovative items of equipment that transform power from a fluid (heavy steam, gas, or water) right into power. The high-speed transforming, extreme temperatures, and stress associated with their operation make routine and complete maintenance vital. One of the standard concepts in turbine maintenance is preventative maintenance. This hostile strategy requires often set up examinations, cleaning up, and little fixings to quit significant failings before they happen. Flow Path Inspections Preventative maintenance normally includes work such as lubricating bearings, examining and transforming clearances, inspecting blades for wear or damage, and watching on vibration degrees. By resolving little problems early, preventative maintenance can considerably reduce the danger of tragic failings and broaden the turbine's operational life. Condition-based maintenance is one more vital idea that has obtained significance with the arrival of innovative keeping an eye on modern innovations. This technique trusts real-time info from sensing devices and watching on systems to recognize when maintenance is important. Requirements such as vibration, temperature degree, pressure, and oil condition are constantly kept track of. When these requirements differ normal varieties, it suggests potential concerns that ask for interest. Condition-based maintenance permits more targeted and efficient maintenance jobs, decreasing unneeded downtime and improving resource part. Preparing for maintenance takes condition-based maintenance an activity far better by using details analytics and expert system solutions to forecast when failings are likely to take place. By examining historic data and existing running issues, preparing for maintenance systems can projection prospective problems prior to they turn up as observable problems. This strategy permits maintenance teams to plan treatments at one of one of the most favorable times, minimizing disruption to operations and making finest use the performance of maintenance tasks. Placement is a vital method in turbine maintenance. Right alignment of the turbine shaft with the generator or driven tools is essential for smooth procedure and longevity. Misalignment can cause excessive vibration, accelerated wear of bearings and seals, and reduced efficiency. Regular placement checks and adjustments, regularly utilizing laser positioning tools, are a standard element of turbine maintenance programs. Balancing is an additional essential aspect of turbine maintenance. The high-speed turning of turbine elements indicates that also little inequalities can result in substantial resonance and put on. Dynamic stabilizing of blades and impellers is executed to make sure smooth procedure. This procedure entails consisting of or getting rid of small amounts of weight at details show complete optimal balance. Regular vibration evaluation helps recognize inconsistency concerns early, permitting timely alterations. Analysis and cleansing of turbine blades are critical maintenance methods. Blades can deal with numerous troubles such as disintegration, corrosion, fouling, or physical problems. Heat Exchanger Maintenance Regular assessments, frequently utilizing borescopes or various other non-destructive screening approaches, assistance identify these troubles. Cleaning up of blades, which might involve chemical cleaning or mechanical methods like grit blasting, assists maintain wind resistant performance and protects versus efficiency damage. Lubrication checking is a vital element of turbine maintenance. Proper lubrication of bearings, equipments, and various other relocating components is vital for reducing rubbing and use. This involves not just making sure an appropriate supply of lubricating substance nonetheless also keeping track of its top quality. Oil analysis is a normal method that assists locate pollutants, placed on fragments, and adjustments in oil property or commercial buildings that can show developing problems in the turbine system. Seal maintenance is another vital strategy. Seals quit leakage of functioning fluids and lubricating materials, and their failure can reason substantial efficiency losses and possible safety and security and safety and security risks. Routine evaluation and replacement of seals, especially in high-pressure or high-temperature locations, is a typical part of turbine maintenance routines. Control system maintenance is increasingly vital as wind turbines happened much more automatic and electronically regulated. This includes regular checks and calibration of sensing units, actuators, and control shutoffs. Software program application updates and cybersecurity procedures are furthermore critical elements of modern-day turbine control system maintenance. Security and security is essential in all turbine maintenance tasks. Wind wind turbines require high energies, extreme temperature level levels, and potentially dangerous products. Strenuous adherence to security methods, consisting of lockout/tagout procedures, limited location access procedures, and correct use of individual safety and security equipment (PPE), is crucial. Safety and security training and typical communication course for maintenance staff members are vital techniques in turbine maintenance programs. Documents and record-keeping are important approaches in turbine maintenance. Comprehensive logs of all maintenance activities, containing assessments, repair service services, and part substitutes, provide valuable historical data for fad examination and future maintenance planning. Lots of organizations currently usage digital maintenance administration systems (CMMS) to boost this treatment and aid with information evaluation. Training and skill advancement of maintenance personnel is a recurring strategy in turbine maintenance. As turbine modern technologies evolve, maintenance techniques and gadgets additionally progression. Routine training programs make certain that maintenance group are upgraded with the most as much as day maintenance methods, diagnostic tools, and safety and safety procedures. Environmental elements to take into consideration are coming to be gradually important in turbine maintenance. This includes ideal dealing with and disposal of hazardous items like used oils and cleansing chemicals. Great deals of maintenance techniques currently focus on reducing ecological influence while making sure optimum turbine effectiveness. Turbine maintenance is a challenging and diverse location that combines mechanical, electrical, and dramatically, electronic knowledge. The essential concepts of preventative, condition-based, and preparing for maintenance develop the foundation of modern-day turbine maintenance techniques. Practices such as alignment, balancing, blade assessment and cleaning, lubrication management, and control system maintenance are vital for assuring the dependability, performance, and longevity of turbine systems. As turbine technologies stay to advancement, maintenance techniques will definitely likewise advancement, including new technologies and approaches to fulfill the difficulties of keeping these essential devices in an ever-changing power landscape.