Wedge vs Ball Bonding: Which Technique Reigns Supreme?

Introduction

In the area of semiconductor packaging and microelectronic meeting, two dominant wire bonding suggestions stand out: wedge bonding and ball bonding. Both approaches are valuable in making certain stable interconnections between chips and substrates, yet they come with distinct facets, blessings, and purposes. This article delves deep into the intricacies of these two twine bonding techniques, imparting a comprehensive prognosis to verify which strategy reigns supreme in a good number of scenarios. Whether you’re a professional engineer or simply beginning your ride in twine bonding expertise, this book will equip you with central insights.

What is Wire Bonding?

Wire bonding is a method used to create electric connections among semiconductor instruments and their applications. It comprises the usage of skinny wires—basically created from gold, aluminum, copper, or silver—which can be thermally or ultrasonically bonded to pads on a chip and substrate. The cord bonding procedure is an important for high-overall performance electronics as it immediately influences reliability, performance, and general instrument high-quality.

The Wire Bonding Process Explained

The twine bonding method will probably be damaged down into a number of key steps:

By information how cord bonding works, you can relish its necessary position in glossy electronics production.

Types of Wire Bonding Techniques

Wire bonding encompasses a lot of tactics tailored for particular purposes:

- Ball Bonding: Involves forming a ball at the conclusion of the wire prior to making a bond.

- Wedge Bonding: Utilizes a wedge-shaped software to create bonds with no forming a ball on the stop.

- Ribbon Bonding: Uses wider ribbons rather then traditional wires for greater floor places.

Each model has its special set of characteristics that influence performance in varied eventualities.

Wedge vs Ball Bonding: A Comparative Overview

When comparing wedge vs ball bonding tactics, that is quintessential to investigate their middle transformations:

1. Bond Formation Mechanism

-

Ball Bonding:

- Begins with heating the wire's finish to style a small ball.

- The ball is then pressed in opposition to the bond pad utilising ultrasonic calories to create a robust attachment.

-

Wedge Bonding:

- Uses a wedge instrument that presses down on the wire with out forming a pre-bonded sphere.

- Bonds are created by means of mechanical stress mixed with heat (thermosonic) or ultrasonic strength.

2. Material Compatibility

Each technique favors special ingredients:

- Ball bonding predominantly uses gold caused by its more advantageous conductivity.

- Wedge bonding can utilize aluminum or copper wires thoroughly.

three. Applications and Industry Use Cases

Both equipment uncover their niche throughout a number of sectors:

-

Ball Bonding:

- Widely utilized in microelectronics like IC packaging through its compatibility with wonderful pitch functions.

-

Wedge Bonding:

- Preferred in potential modules and automotive electronics wherein larger pads are widely used.

four. Cost Consideration

Cost performs an good role in opting for among those tricks:

| Feature | Ball Bonding | Wedge Bonding | |------------------|--------------------------|---------------------------| | Material Cost | Higher (Gold) | Lower (Aluminum/Copper) | | Equipment Cost | Typically top | Generally lower |

5. Reliability Factors

Reliability is paramount in digital packages:

- Ball bonds have a tendency to convey more effective fatigue resistance less than thermal biking conditions.

- Wedge bonds offer very good moisture resistance by means of their shrink pressure phases on pads.

Detailed Analysis of Wedge Bonding Process

What Makes Wedge Bonding Unique?

Wedge bonding sticks out attributable to its elementary but effective mechanism for developing strong connections among chips and substrates without needing a pre-bonded sphere:

Key Advantages

Applications

Wedge bonding finds software throughout dissimilar industries including:

- Automotive electronics

- Power modules

- Aerospace components

Understanding Wedge Wire Bonding Machines

The good fortune of wedge bonding heavily is based on difficult methods designed peculiarly for this purpose:

In-intensity Look at Ball Bonding Process

What Defines Ball Bonding?

Ball bonding is commonly appreciated in prime-density programs the place space is limited yet efficiency demands stay high:

Key Features

Applications

Ball bonding excels peculiarly in sectors consisting of:

- Microelectronics

- Telecommunications

- High-frequency RF applications

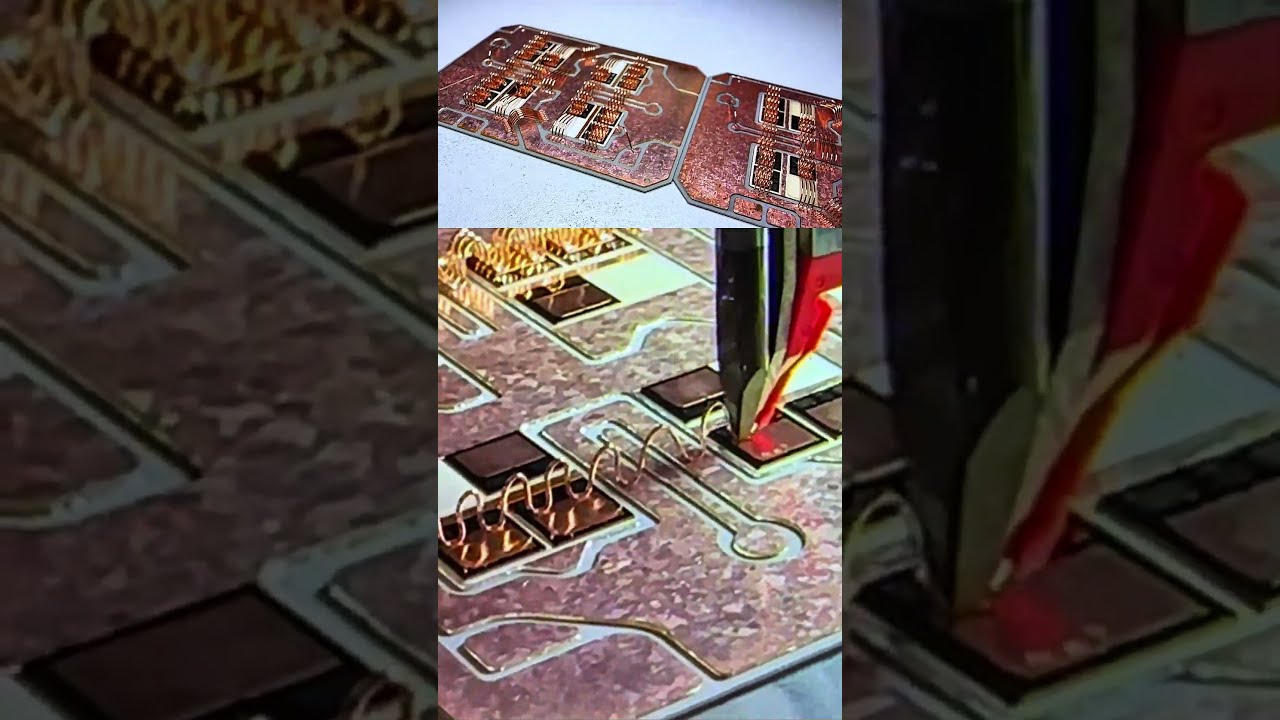

Exploring Ball Wire Bonding Machines

To acquire top-rated functionality all over ball bonding methods, specialized machinery is utilized:

Evaluating Wire Bond Quality Control Measures

Quality management during equally processes cannot be overstated because it at once affects yield premiums and product reliability:

1. Inspection Methods

Various inspection thoughts determine that bonds meet stringent business specifications:

| Inspection Method | Description | |-------------------------|--------------------------------------------------| | Visual Inspection | Manual checks by means of operators via magnification | | Pull Test | Evaluates the strength of special bonds | | Shear Test | Assesses adhesive capability between layers |

2. Common Failure Modes

Understanding talents failure modes is helping mitigate negative aspects related to each technology:

For Ball Bonds:

- Incomplete Bonds

- Oxidation Issues

For Wedge Bonds:

- Heel Cracking

- Pad Damage

Implement rigorous inspections publish-process to catch trouble early formerly they impression downstream production stages.

Advantages and Disadvantages of Each Technique

When deciding between wedge vs ball bonding, reflect on these pros and cons which could have an impact on your creation line choices tremendously:

Advantages of Ball Bonding

Disadvantages of Ball Bonding

Advantages of Wedge Bonding

Disadvantages of Wedge Bonding

FAQs About Wedge vs Ball Bonding Techniques

Here are some by and large requested questions regarding these two necessary tactics:

1. What’s the most important distinction among wedge and ball bonding?

The standard difference lies of their bond formation mechanism; ball bonding makes use of a melted sphere even though wedge employs direct power with out pre-formations ensuing in unique advantages founded on application desires!

aluminum wire bonding2. When must always I decide on one method over any other?

If you're looking at compact designs involving great pitches—go with ball bonds! However if working inside vitality modules requiring sturdiness—wedge may well serve pleasant the following instead!

3. Are there particular constituents solely gorgeous for one strategy?

Yes certainly! Gold works top-rated with balls when aluminum/copper excel below wedges! Make positive you want accurately structured upon your challenge standards!

four. How does every single technique have an effect on long-term reliability?

Generally speakme—a nicely-accomplished ball bond displays superior fatigue resistance! While wedges convey notable moisture safety ensuring durability regardless!

5.Who gives working towards substances on those techniques?

Many universities present programs alongside such a big amount of on line systems web hosting tutorials & webinars focused explicitly upon improving competencies round these principal technologies!!

Conclusion

Choosing between wedge vs ball bonding in a roundabout way boils down individual alternative dictated via detailed venture parameters—concerns together with subject matter resolution,value causes,and wanted efficiency effects play pivotal roles influencing this decision-making procedure immensely!

Both processes have distinctive strengths; therefore awareness your application’s one of a kind calls for enables you leverage both system properly whereas maximizing productivity yields throughout production cycles forward!