The Role of Wire Bonding in Semiconductor Manufacturing

Introduction

In the quick-paced world of semiconductor production, every detail topics. One principal part that on the whole goes overlooked is the twine bonding procedure. This process serves as an critical link among chips and substrates, making certain legitimate performance in a myriad of electronic instruments. In this newsletter, we shall delve deep into the function of cord bonding in semiconductor production, exploring several techniques, applications, demanding situations, and long run trends.

The Role of Wire Bonding in Semiconductor Manufacturing

Wire bonding is a pivotal activity in semiconductor packaging that connects included circuits (ICs) to their respective substrates or leads by thin steel wires. This procedure has been around for decades and maintains to evolve with improvements in science. The most important goal of cord bonding is to create electric connections which are equally sturdy and sturdy lower than numerous environmental stipulations.

Understanding the Wire Bonding Process

The wire bonding system consists of a couple of steps:

-

Preparation: The first step includes cleansing the surfaces of the chip and substrate to determine top adhesion.

-

Placement: Wires are put onto explicit bonding pads at the chip and substrate by means of a bonding gadget.

-

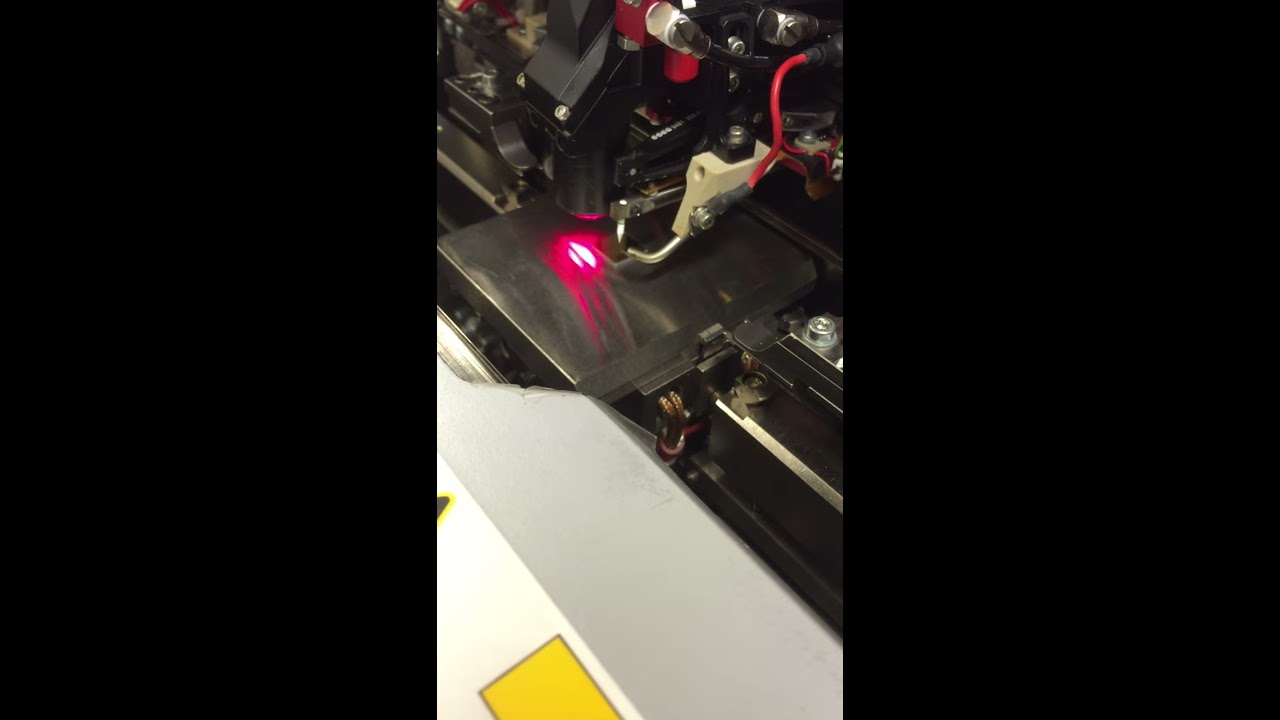

Bonding: The bonding itself will also be finished through a good number of methods corresponding to thermosonic or ultrasonic bonding. The software of warmth and force factors the twine to bond completely.

-

Inspection: Post-bonding inspections are carried out making use of quite a few non-damaging testing approaches to make certain bond good quality.

Types of Wire Bonding Techniques

There are several different types of wire bonding systems utilized in semiconductor manufacturing:

Ball Bonding: This familiar procedure utilizes a small ball shaped at the cease of a gold wire or aluminum wire. It's as a rule used due to its simplicity and reliability.

Wedge Bonding: This process employs a wedge-fashioned tool for connecting wires. It is exceedingly priceless for top-frequency functions wherein low inductance is vital.

Ribbon Bonding: Ribbon wires be offering a bigger floor house for connections, making them proper for vitality modules and high-present functions.

Fine Pitch Wire Bonding: As IC designs emerge as extra compact, great pitch cord bonding procedures have emerged to handle tighter spacing between connections.

Wire Bonding Equipment: An Overview

To participate in potent wire bonding, specialised appliance is required:

-

Wire Bonding Machines: These machines are available automated or semi-computerized configurations and are designed namely for high-amount construction.

-

Bond Tools: Various gear along with capillary tubes and ultrasonic resources play mammoth roles in accomplishing exact bonds.

-

Inspection Tools: Equipment like X-ray machines and pull testers are quintessential for evaluating bond integrity after production.

Applications of Wire Bonding Technology

Wire bonding unearths large packages throughout a whole lot of sectors:

Wire Bonding in Electronics

From smartphones to computers, close to each digital system is predicated on successful twine bonding for functionality stability. It guarantees effective electric connections inside of problematical circuitry.

Power Electronics Wire Bonding

Power modules utilize thicker wires in a position to dealing with top currents whilst maintaining thermal control standards—this is where ribbon or thick cord bonding comes into play.

Wire Bonding for Medical Devices

Reliability is paramount in medical electronics; in this case, rigorous requirements govern wire bonding tactics in contraptions like pacemakers or diagnostic tools.

RF Module Wire Bonding

Radio Frequency (RF) modules receive advantages from low inductance connections made you can actually through complicated wedge or ball bonding methods, enhancing sign integrity for the duration of conversation tactics.

Challenges Faced in Wire Bonding Reliability

While twine bonding science maintains to develop, it faces varied challenges that could effect reliability:

1. Environmental Factors

Environmental controls which includes humidity and temperature play primary roles in bond satisfactory. Moisture can end in corrosion at the same time as severe temperatures may impression cloth homes over time.

2. Material Selection

Choosing among gold vs aluminum twine bonding includes balancing expense against functionality aspects like oxidation resistance and thermal conductivity.

three. Process Control

Maintaining stringent course of keep watch over all over manufacturing enables mitigate dangers associated with defects along with heel cracks or incomplete bonds—both dangerous to software performance.

Wire Bond Failure Analysis: Understanding Defects

Failure analysis becomes basic while evaluating why confident bonds fail:

Common Failure Modes:

- Bond Lifting: Often brought on by inadequate strength at some stage in bond formation.

- Heel Cracks: Result from thermal stress all the way through operation.

- Incomplete Bonds: May arise by means of poor surface training earlier wiring begins.

Non-unfavourable Testing Methods: Using tactics like x-ray imaging or shear assessments helps name weak bonds without dangerous formula—a relevant step closer to guaranteeing product reliability formerly industry unlock.

Cost Considerations in Wire Bonding

The payment associated with assorted different types of cord bonding can notably influence basic mission budgets:

| Type | Cost in line with Unit | Advantages | |---------------------|---------------|-------------------------------------| | Gold Wire Bonding | High | Excellent conductivity; oxidation resistant | | Aluminum Wire Bonding | Moderate | Cost-mighty; extraordinary mechanical force | | Copper Wire Bonding | Low | Lower subject material charges; higher conductivity |

When considering that "wire bonding expense," it’s integral to judge these motives along favored overall performance requirements tailored in the direction of distinctive functions—this helps firms to select correctly stylish on their ambitions whilst controlling fees quite simply!

Quality Control Measures in Wire Bonding Processes

To be certain that prime consequences all the way through manufacturing runs:

Regular inspections should still be carried out at more than one tiers across manufacturing—from preliminary setup using final output exams.

Implement standardized running strategies (SOPs) concentrating on important parameters reminiscent of bond electricity calibration, pressure settings changes, and the like., which without delay have an impact on long-term steadiness outcomes!

Employ statistical method regulate (SPC) methodologies anytime attainable—these furnish insights into anomalies going on over the years permitting timely corrective activities if worthy!

Conduct popular tuition sessions aimed at maintaining operators updated involving cutting-edge superb practices inside marketplace concepts—this fosters continual enchancment all over all degrees in contact!

Future Trends in Wire Bond Technology

As we Visit this site seem to be forward closer to new tendencies shaping the landscape surrounding semiconductor production—a couple of noteworthy developments emerge:

Innovative Materials

Developments within composite resources promise lighter but more potent options in comparison with typical metals—probably revolutionizing how we frame of mind wiring treatments henceforth!

Automation & Industry four.0 Integration

Increased automation functions along sensible applied sciences pave pathways toward stronger effectivity throughout operations—ultimately cutting human error quotes at the same time as streamlining methods similarly than ever before noticeable traditionally!

Low Temperature & High Frequency Solutions

Emerging demands call forth improvements focused on minimize-temperature environments coupled with top-frequency standards—a mission met using ongoing investigation projects from quite a number stakeholders engaged within this dynamic box immediately!

FAQs About Wire Bonding

Q1: What is cord bonding?

A1: Wire bonding refers to a approach utilized in semiconductor packaging that connects included circuits (ICs) to their substrates via thin steel wires.

Q2: How does the twine bonding task paintings?

A2: The course of involves striking a skinny steel wire onto one-of-a-kind pads on an IC and substrate via warmth and pressure till they type a permanent connection with the aid of tips like thermosonic or ultrasonic tactics.

Q3: What are in style varieties of cord bonds?

A3: Common versions embody ball bonds (making use of round assistance), wedge bonds (flat-ended), ribbon bonds (wider surface domain), amongst others tailored in opposition to selected functions relying upon requisites needed therein!

Q4: Why is satisfactory regulate important in cord bonding?

A4: Quality manipulate guarantees that each bond meets market specifications concerning reliability aspects which at last have an impact on tool performance—poorly bonded components may perhaps lead no longer simplest untimely disasters yet additionally steeply-priced remembers down line impacting profitability appreciably over time!

Q5: What ingredients are most commonly used for wiring?

A5: Common material comprise gold, aluminum, copper, or silver—all chosen centered on their conductive residences alongside concerns related to expenditures linked to every variety certain as a consequence whilst essential depending upon finish-use scenarios envisioned forward!

Q6: How do I operate failure diagnosis on bonded wires?

A6: Utilizing non-unfavorable testing methods like x-ray imaging mixed with shear checks lets in engineers chances determining underlying points with out unfavourable formulation themselves guaranteeing thorough reviews carried out correctly for the duration of lifecycle stages encountered relocating ahead thereafter too!

Conclusion

The function of twine bonding in semiconductor production can't be overstated—it serves as one key thing connecting limitless contraptions vitalizing progressive lifestyles when paving pathways against long run innovations anticipated emerging quickly thereafter another time enriching society overall certainly along method! As era maintains evolving hand-in-hand along those developments bringing forth new methodologies bettering functionality reliability necessities estimated repeatedly increasing forward in the end ushered guiding standards governing this tricky subject forevermore yielding benefits skilled widely across industries flourishing amid increasing calls for witnessed world wide today world wide!