Selecting the Best Wires for Semiconductor Bonding Applications

Introduction

In the ever-evolving panorama of electronics and semiconductor production, twine bonding has emerged as a principal strategy. This technique includes making electric connections between semiconductor devices and their packaging utilising effective wires. Selecting the high-quality wires for semiconductor bonding functions is paramount to attaining reliability, efficiency, and payment-effectiveness. With a great number of material achieveable—gold, aluminum, copper, and silver—every with its unique properties and applications—the selection on which cord to take advantage of can vastly affect the caliber of the remaining product.

This article explores every area of cord bonding in semiconductor functions, from knowledge the wire bonding technique to reading special ways and technology. We'll delve into the intricacies of twine components selection, reliability causes, widely wide-spread failures, and enterprise improvements. Whether you might be an engineer in search of insights or a organization aiming to optimize your tactics, this accomplished booklet will serve as a useful source.

What is Wire Bonding?

Wire bonding is a central manner used usually in semiconductor manufacturing to create electrical connections among incorporated circuits (ICs) and their respective substrates. The wire bonding procedure quite often employs thin wires produced from conductive resources including gold or aluminum to ascertain these connections.

How Wire Bonding Works

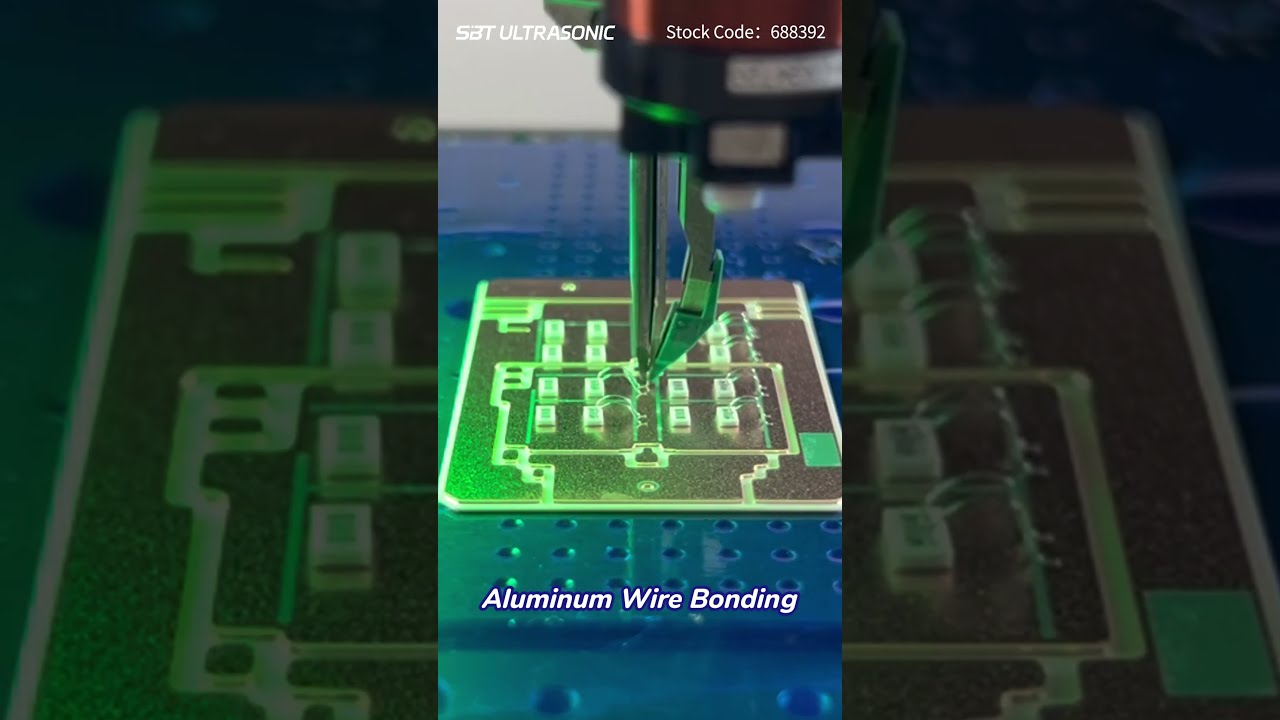

The wire bonding technique consists of attaching one stop of a thin twine to a bond pad on the chip although securing the alternative finish to a lead body or substrate. The connection is formed by thermal potential, strain, or ultrasonic vibrations that meld the steel surfaces together. Understanding how wire bonding works lays the foundation for selecting the top-quality wires for exclusive programs.

Types of Wire Bonding Techniques

There are countless kinds of cord bonding techniques utilized in semiconductor manufacturing:

Each system has its benefits and disadvantages; consequently, it's essential to judge correctly primarily based on program standards.

Wire Bonding Technology Overview

The improvements in twine bonding technological know-how have enabled brands to enhance yield costs, slash expenditures, and advance product functionality in semiconductors.

Wire Bonding Equipment

Wire bonding gear consists of really expert machines designed for exceptional bonding programs corresponding to ball bonders and wedge bonders. These machines will probably be manual or fully automated relying on production wishes. Factors including speed, precision, and ease of use need to be thought about when selecting package in your facility.

Cost Considerations in Wire Bonding

When on the grounds that twine bonding rates, one needs to account not simply for material fees yet also desktop operation fees, hard work expenses, and achievable remodel as a result of disasters. Evaluating these facets guarantees that you just make informed decisions about your construction approach.

Selecting Wires for Semiconductor Applications

Choosing proper wires performs a obligatory role in ensuring best efficiency and durability of electronic gadgets.

Gold vs Aluminum Wire Bonding

Gold twine bonding supplies super conductivity but comes with larger material prices when compared to aluminum. On the other hand, aluminum is extra expense-superb yet might not furnish identical levels of reliability in precise environments.

Table 1: Comparison Between Gold and Aluminum Wires

| Property | Gold Wire | Aluminum Wire | |-----------------------|----------------------|----------------------| | Cost | High | Low | | Conductivity | Excellent | Good | | Oxidation Resistance | High | Moderate | | Temperature Tolerance | High | Moderate |

Copper Wire Bonding Benefits

Copper wires are gaining attractiveness as a consequence of their top of the line conductivity compared to gold and aluminum at minimize quotes; but it, additionally they reward demanding situations with regards to oxidation.

Silver Wire Bonding Applications

Silver presents the best option conductivity however would be at risk of tarnishing over the years; for this reason it’s in many instances used in niche packages in which performance outweighs charge considerations.

Wire Bonding Quality Control Measures

Quality control is relevant all the way through all ranges of twine bonding operations—from textile decision through to last inspection.

Wire Bond Inspection Methods

Various inspection techniques are utilized for the duration of construction:

- Visual Inspection

- X-ray Inspection

- Pull Testing

- Shear Testing

These approaches help discover defects early on whilst making certain compliance with industry criteria like JEDEC hints.

Common Wire Bond Failures and Analysis

Understanding accepted failure modes can tremendously fortify reliability in creation:

Table 2: Common Failure Modes & Solutions

| Failure Mode | Description | Solution | |----------------------|----------------------------------|----------------------------------| | Bond Pad Damage | Physical spoil from tooling | Calibrate drive settings | | Incomplete Bonds | Poor attachment | Adjust persistent settings | | Oxidation Issues | Surface degradation | Implement shielding measures | | Bond Lifting | Insufficient adhesion | Optimize cleaning tactics |

Wire Bond Process Control Techniques

Effective job manipulate leads in an instant toward superior product high-quality through minimizing variability throughout operations:

Implementing these controls creates a solid creation surroundings conducive for nontoxic effects.

Applications of Wire Bonding in Semiconductors

Wire bonding reveals large program across varied sectors within electronics:

Wire Bonding in Automotive Electronics

Automotive electronics count number heavily on tough wiring connections due to the harsh running stipulations like temperature fluctuations and mechanical vibrations—therefore necessitating satisfactory bonds due to efficient techniques such as thermosonic wedge bonding or positive pitch ball bonding processes tailored principally for automobile constituents.

Wire Bonding Innovations for Medical Devices

In medical instrument manufacturing wherein precision matters critically—creative procedures riding micro-size bonded wires allow compact designs crucially aiding patient protection devoid of compromising capability for that reason improving equally healing effectiveness whilst lowering overall dimension constraints imposed until now via out of date designs employing usual tricks on my own!

FAQ Section

1. What is wire bonding?

Wire bonding refers no longer in simple terms generally refers returned against connecting chips inside of digital assemblies yet additionally Great post to read encompasses plenty of extraordinary methodologies hired established upon wanted attributes in demand along with flexibility with regards to geometrical constraints inherent in the course of various industries ranging from aerospace due to automobile markets alike!

2. How does gold compare with aluminum for twine bonding?

Gold gives you gold standard conductivity alongside resistance in opposition to corrosion whereas aluminum grants affordability coupled along adequate overall performance — ultimately major engineers desiring take into accounts change-offs elegant upon given calls for existing themselves subsequently!

three. What are some user-friendly failures associated with cord bonds?

Common problems encompass incomplete bonds superior in opposition t compromised connections together with oxidization imparting itself over prolonged publicity beneath damaging prerequisites necessitating popular inspections carried out frequently making sure sustained integrity right through lifespan monitored closely!

4.Can copper be used thoroughly inside of any specific context?

Indeed yes! Copper stands out specially when dealing in particular around high-overall performance environments owing largely attributed toward marvelous conductive homes exhibited typically yielding favorable outcomes established invariably throughout distinctive initiatives undertaken successfully!

5.What inspection tools are handy for the period of this complete strategy?

Several methodologies exist inclusive of visual checks carried out manually against computerized solutions making use of x-rays permitting thorough verification without compromising potency thereby declaring continually prime output standards performed seamlessly!

6.Where may I locate further sources around this subject matter?

A breadth exists encompassing housing designated tutorials hosted on line overlaying all the pieces involving basic ideas along complex concepts hired safely yielding potent outcomes carried out always across multiple tasks undertaken diligently striving in opposition t excellence continuously pursued inside engineering nation-states at the present time!

Conclusion

Selecting the Best Wires for Semiconductor Bonding Applications isn’t with reference to making a choice on a fabric; it’s about expertise how that desire affects each part of manufacturing—from reliability considerations proper thru can charge implications—and how it aligns with marketplace developments moving ahead into long term generations inside of know-how-pushed industries speedily evolving day-by-day! By grasping those facets thoroughly at the same time as exploring inventive strategies sold normally at the moment we empower ourselves in the direction of achieving excellence perennially well known tirelessly within each box recreation pursued!