Mastering Wire Bonding Techniques for Superior Results

Introduction

In the short-evolving international of electronics and semiconductor production, the cord bonding process stands as a very important method for making riskless electric connections. From included circuits to force modules, know-how and studying twine bonding methods can appreciably fortify product efficiency and reliability. This article delves into the problematic data of twine bonding technological know-how, exploring loads of systems, functions, tools, disasters, and answers to be sure that choicest results.

With a spotlight on real looking insights and technical intensity, this entire assist aims to deliver engineers, brands, and students with the understanding fundamental to excel in twine bonding. Whether you’re a seasoned pro or a newcomer inside the container, studying wire bonding innovations is major for accomplishing satisfactory electronic assemblies.

What is Wire Bonding?

Wire bonding refers back to the activity of connecting two metal surfaces using a skinny twine that creates an electrical bond. This formula is widely utilized in semiconductor packaging and electronic tool meeting to ascertain connections among chips and substrates or inside of multi-chip modules.

The Importance of Wire Bonding in Electronics

Wire bonding performs a quintessential position in making sure electric conductivity and mechanical balance inside electronic units. Its importance extends throughout numerous industries:

- Semiconductors: Essential for chip-to-chip communication.

- Automotive Electronics: Critical for safe practices techniques like airbags.

- Medical Devices: Ensures reliability in life-saving units.

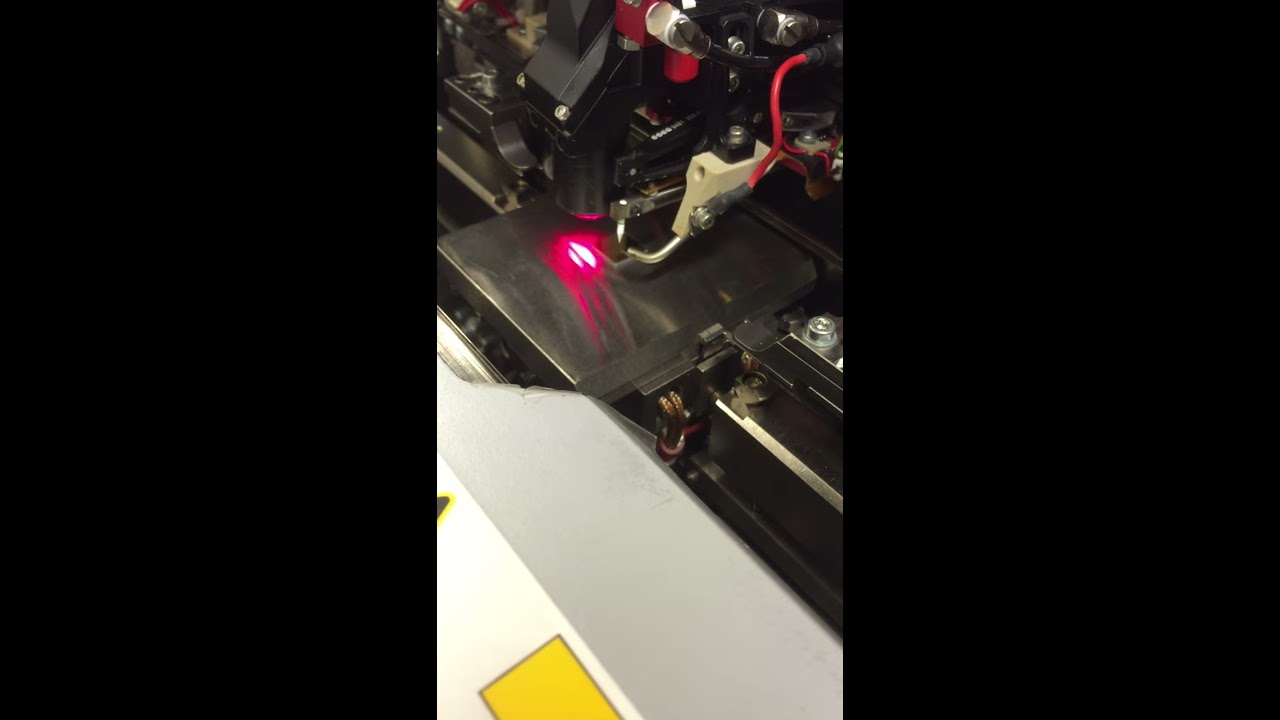

How Wire Bonding Works

The cord bonding task includes a number of steps:

Understanding how those phases engage allows engineers to optimize conditions for higher bond caliber.

Types of Wire Bonding Techniques

When discussing wire bonding ideas, that is the most important to appreciate that there are a couple of strategies tailored for diversified functions:

Ball Bonding Process

Ball bonding includes creating a small ball on the cease of the cord ahead of it makes contact with the substrate. This system is usually used via its efficiency and reliability.

Advantages:

- High energy bonds

- Suitable for great pitch applications

Disadvantages:

- Requires excellent keep watch over of parameters which include heat and pressure

Wedge Bonding Process

Wedge bonding utilizes a wedge-fashioned tool that presses promptly onto the material floor without forming a ball. This strategy is sometimes desired when working with aluminum wires.

Advantages:

- Lower check compared to gold

- Ideal for gigantic-part bonds

Disadvantages:

- May no longer obtain as powerful a bond as ball bonding

Ribbon Bonding Technique

This technique uses flat ribbons instead of round wires, bearing in mind higher surface zone contact which may end in expanded thermal functionality.

Applications:

- Power modules

- High-frequency devices

Wire Bonding Equipment Overview

To accurately execute any cord bonding technique, one of a kind equipment and tools are required:

Wire Bonding Machine Types

- Operated manually; accurate for low-extent manufacturing.

- Combines guide input with computerized controls; affords flexibility.

- Ideal for high-quantity construction; maximizes performance and consistency.

Key Components of Wire Bonding Machines

| Component | Function | |--------------------------|-----------------------------------------------| | Ultrasonic Generator | Provides ultrasonic vitality for bonding | | Heated Capillary Tool | Applies warmth all the way through bond formation | | Programmable Logic Control| Automates gadget operations |

Choosing the Right Wire Bonding Method

Selecting the suitable twine bonding system relies upon on multiple causes which include fabric homes, application requisites, and money considerations.

Gold vs Aluminum Wire Bonding

When finding out among gold or aluminum wire bonding, engineers must assess:

- Cost implications (aluminum is sometimes more cost effective)

- Required electrical features (gold gives you top-quality conductivity)

Copper Wire Bonding Advantages

Copper has turned into more and more sought after as it affords first rate electrical efficiency at reduce bills compared to gold or aluminum.

Factors Influencing Selection

Wire Bonding Applications Across Industries

The versatility of twine bonding science lets in it to be utilized across plenty of sectors:

Wire Bonding in Semiconductors

Semiconductor devices count number seriously on amazing interconnections finished due to productive twine bonding ways.

Key Uses:

- Chip packaging

- Multi-die configurations

Wire Bonding for Automotive Electronics

In automobile applications, the place reliability is paramount through safeguard problems, progressed cord bonding ways are hired commonly.

Examples:

- Airbag systems

- Engine manage units

Wire Bonding Failure Analysis

Despite developments in technologies, mess ups can take place for the period of the cord bonding procedure:

Common Failure Modes

Conducting Failure Analysis

To deal with wedge wire bonding these subject matters efficiently:

Mastering Wire Bond Quality Control

Ensuring high-quality bonds is necessary in sustaining product reliability:

Quality Control Techniques

Visual Inspection

Regular visible checks aid catch defects early on.

Automated Inspection Systems

Implement robotic strategies organized with imaginative and prescient sensors for actual-time tracking.

Understanding Wire Bond Reliability

Reliability tests are obligatory in predicting lengthy-time period functionality:

Factors Impacting Reliability

By working out these components, engineers can layout extra resilient products due to strategic fabric range and processing prerequisites.

Advanced Topics in Wire Bond Technology

As know-how evolves, so do methodologies surrounding cord bonding:

Low Temperature Wire Bonding

Emerging constituents require variations in conventional techniques—low-temperature systems let robust connections with no dangerous delicate resources.

Industry four.0 Integration

Adopting shrewd manufacturing concepts enhances automation throughout the time of production lines, expanding effectivity when chopping human mistakes all through wiring techniques.

Learning Resources on Wire Bond Techniques

For these occupied with deepening their potential about wire bonding techniques:

Conclusion

Mastering wire bonding procedures calls for an expertise that spans user-friendly ideas simply by stepped forward functions across a considerable number of industries. By leveraging sleek applied sciences along usual practices reminiscent of great manipulate measures and failure diagnosis workouts—engineers can confirm their merchandise meet rigorous requisites whilst pushing forward innovation limitations inside of electronics manufacturing ecosystems around the world!

FAQs approximately Wire Bonding Techniques

What substances are probably used in wire bonding?

Most broadly used fabrics incorporate gold, aluminum, copper, and silver owing to their fabulous conductivity.

How does environmental handle have an affect on cord bonds?

Controlling humidity stages reduces oxidation disadvantages which make a contribution extensively in the direction of recuperating long-time period reliability result.

What points outcome the choice between ball bonder vs wedge bonder?

Factors equivalent to software sort, check constraints, and desired bond strength play pivotal roles right here.

ol10/# What position does classes play in winning implementation?

Training guarantees technicians comprehend operational nuances premier in the direction of fewer error which at last supports common production great innovations through the years.

6 . hr13hr13/##

In this great exploration into gaining knowledge of twine-bond methods—whether or not you're crafting intricate microelectronics or powerful automobile solutions—there may be perpetually more room for development!