Exploring Ribbon Bonding Applications in Diverse Industries

Introduction

In the world of electronics and semiconductor production, cord bonding has emerged as a principal manner for establishing electric connections between method. Among the different ways of wire bonding, ribbon bonding stands proud attributable to its targeted benefits and flexibility throughout distinct industries. This article delves into the difficult landscape of ribbon bonding packages, exploring how this resourceful know-how is revolutionizing sectors reminiscent of car, aerospace, scientific units, and more.

What is Wire Bonding?

Wire bonding is a approach used to create electrical connections between semiconductor contraptions and their packaging. It comprises driving skinny wires to attach bond pads on an included circuit (IC) to external leads or other chips. The customary intention of wire bonding is to make sure risk-free and productive communication inside digital instruments.

How Wire Bonding Works

The cord bonding system basically entails several steps:

This formula can make use of a range of sorts of materials adding gold, aluminum, copper, and silver twine bonding concepts.

Types of Wire Bonding Techniques

- Ball Bonding: Utilizes a small ball fashioned at the finish of the wire for connections.

- Wedge Bonding: Employs a wedge-fashioned tool rather than a ball for making connections.

- Ribbon Bonding: Uses flat ribbons in place of around wires to make electrical connections.

In abstract, information those basics sets the level for diving deeper into ribbon bonding peculiarly.

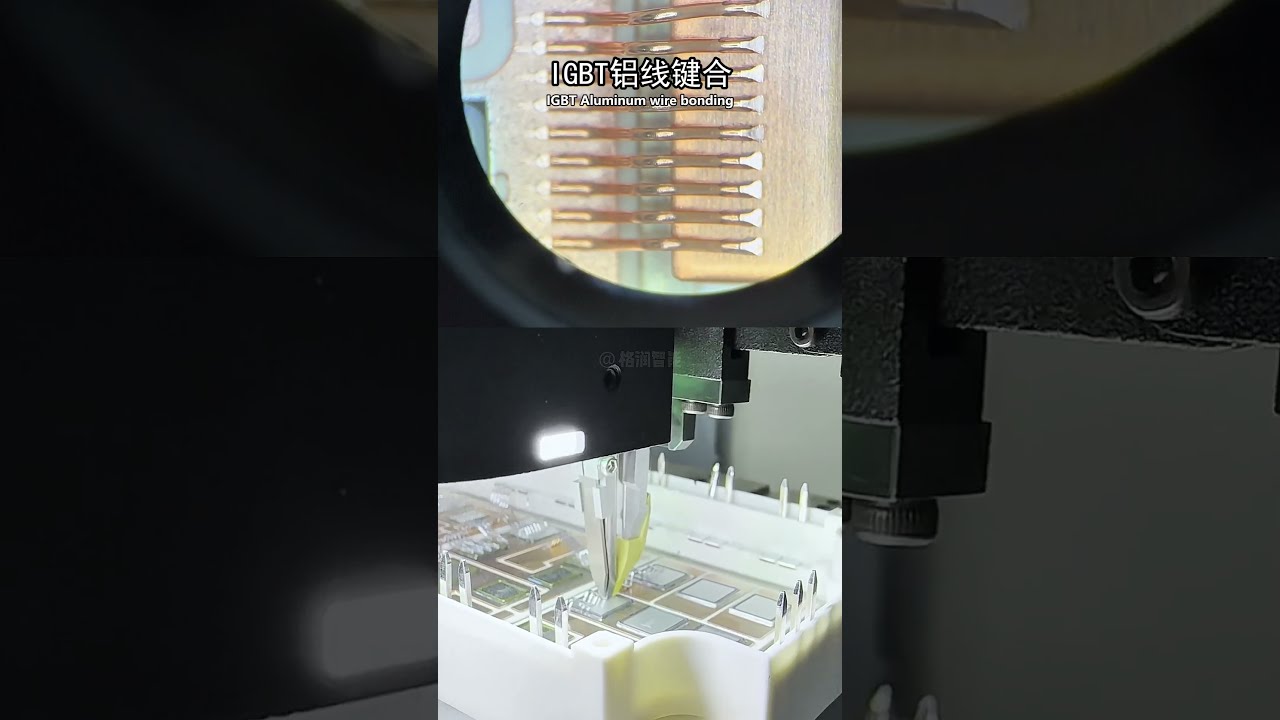

The Ribbon Bonding Process

Ribbon bonding is a sophisticated kind of twine bonding that makes use of flat ribbons other than round wires. This method has received traction because of its capacity to address top cutting-edge densities and present scale back inductance paths compared to conventional around wires.

Advantages of Ribbon Bonding

Ribbon Bonding Machine Overview

A specialised ribbon bonding gadget is obligatory for executing this manner simply. These machines are designed with traits that enable designated keep Browse this site an eye on over parameters like temperature and pressure at some stage in bonding.

Exploring Ribbon Bonding Applications in Diverse Industries

The versatility of ribbon bonding makes it applicable in diverse fields inclusive of:

1. Automotive Electronics

In fashionable automobiles where digital procedures are integral for method like sensors and infotainment approaches, ribbon bonding affords reliability beneath harsh conditions.

Applications

- Power modules

- Sensor interfaces

2. Aerospace

Aerospace applications require light-weight yet powerful strategies; for this reason, ribbon bonding technological know-how affords competent functionality whilst adhering to strict weight restrictions.

Applications

- Satellite verbal exchange systems

- Flight manipulate systems

3. Medical Devices

Medical units necessitate reliability wherein human lives are at stake; thus ribbon bonded connections be certain minimal failure costs and lengthy-term reliability.

Applications

- Diagnostic equipment

- Implantable devices

4. Telecommunications

With excessive details rates being demanded by way of networks in these days, ribbon bonding’s low inductance residences make it superior for RF modules used in telecommunications package.

Applications

- Base station transceivers

- Optical communication devices

Understanding Ribbon Wire Bonding Techniques

Gold vs Aluminum Ribbon Bonding

When picking out substances for ribbon bonding, many engineers debate between gold and aluminum ribbons:

| Feature | Gold Ribbon | Aluminum Ribbon | |-----------------------------|----------------------|-----------------------| | Cost | High | Low | | Corrosion Resistance | Excellent | Moderate | | Electrical Conductivity | Superior | Good | | Application | High-cease electronics | General-function |

In summary, when gold ribbons provide most popular conductivity and corrosion resistance, aluminum may well be most suitable the place check is a worry.

Ribbon Bonding vs Wedge Bonding

Both systems have their region in manufacturing; nevertheless it, they cater to one-of-a-kind needs situated on application requirements:

Comparison Table

| Feature | Ribbon Bonding | Wedge Bonding | |-----------------------------|----------------------|-----------------------| | Material | Flat ribbons | Round or flat wires | | Typical Application | High-density circuits | General IC interconnections | | Process Speed | Faster | Moderate |

While the two tips can achieve tremendous outcomes; engineers typically decide upon established on categorical design constraints akin to space obstacles or thermal homes.

Challenges in Ribbon Bonding

Despite its reward, there are demanding situations linked to ribbon bonding that want addressing:

To mitigate those challenges, corporations sometimes invest in lessons courses specializing in high-quality management measures tailored exceptionally for ribbon bonding methods.

FAQs About Ribbon Bonding

1. What industries chiefly use ribbon bonding?

Ribbon bonding unearths applications broadly speaking in car electronics, aerospace production, clinical devices construction, and telecommunications sectors attributable to its uncommon reward over normal techniques.

2. How does ribbon measurement have effects on overall performance?

Larger ribbon sizes mostly enable larger modern capacities yet may just include business-offs relating to mechanical flexibility or thermal dissipation traits; thus cautious attention is crucial based on application desires.

three. Can I use any sort of subject material for ribbon bonding?

While aluminum and gold are customary decisions as a result of their conductivity homes; that is indispensable to evaluate compatibility with your detailed utility sooner than determining any subject material category for maximum outcomes.

4. What aspects have an impact on bond force throughout the approach?

Factors embody fabric category used (gold vs aluminum), ambient running situations (temperature/humidity), adhesion processes hired (ultrasonic vs thermosonic), amongst others which all play principal roles influencing ordinary bond integrity publish-course of of entirety.

5. Are there working towards assets to be had for finding out about twine/ribbon bonding?

Yes! Numerous universities present programs centered on sides surrounding contemporary methods like these fascinated with the two cord & mainly inside components connected quickly closer to fine implementation techniques around applying this era correctly!

6. What's next for ribbon era ideas?

As demand continues starting to be throughout a couple of sectors witnessing improvements on daily basis—from elevated automation expertise because of AI integration fostering smarter determination-making tactics—to stronger cloth studies paving means closer to novel purposes expanding beyond regular utilizations viewed in these days!

Conclusion

In conclusion, exploring ribbon bonding functions well-knownshows its pivotal role throughout plenty of industries from automobile electronics to scientific gadgets and past. By leveraging its enjoyable attributes consisting of high existing capability and lowered inductance pathways—engineers can drive innovation when ensuring reliability within their designs! As we transfer forward into an technology fueled through rapid technological developments—ribbon bonds will indubitably stay at leading edge shaping long term landscapes inside of electronic production geographical regions!

This article now not solely highlights quintessential components on the topic of “Exploring Ribbon Bonding Applications in Diverse Industries,” yet additionally serves as an informative resource aimed at improving know-how surrounding procedures integral in opposition t advancing engineering practices shifting forward!