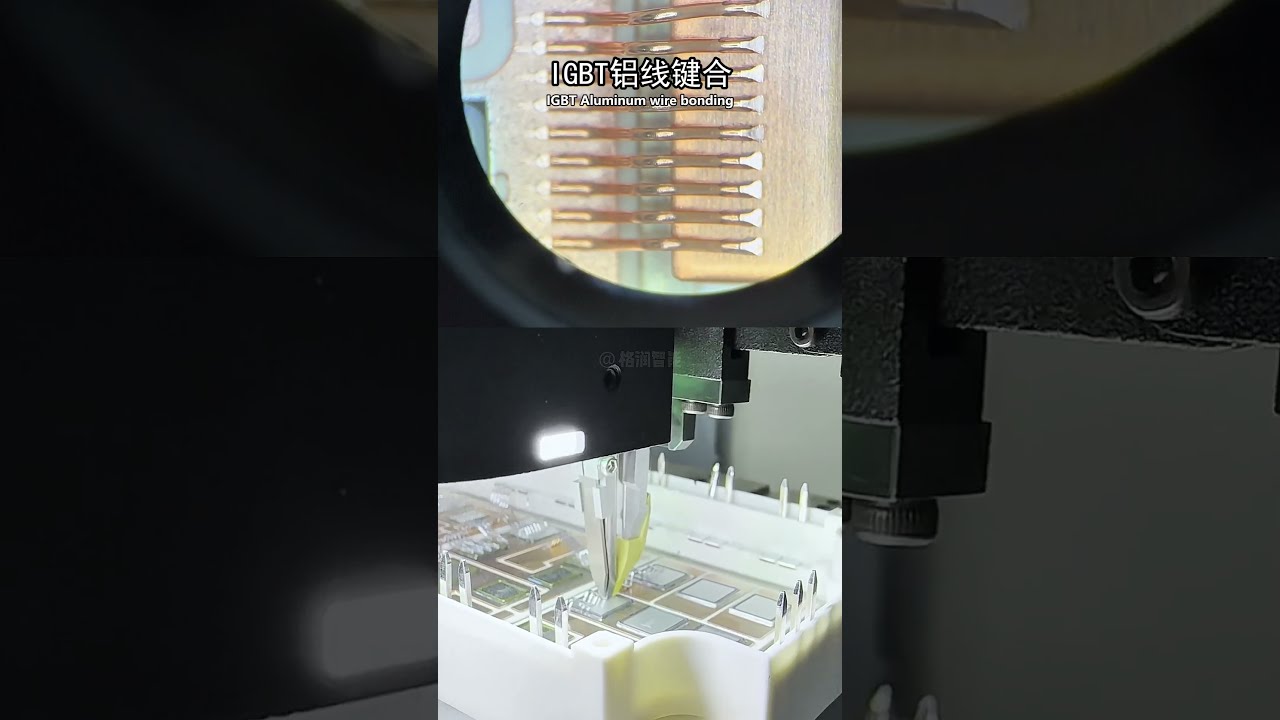

Aluminum Wire Bonding: Methods and Applications

Introduction

Aluminum wire bonding has emerged as a severe job within the realm of electronics manufacturing, primarily within the semiconductor enterprise. As technologies advances, the want for competent, reputable tactics of connecting chips to substrates becomes ever extra paramount. This article delves into aluminum cord bonding, exploring its tips, packages, blessings, challenges, and destiny traits. By expertise these points, professionals could make counseled choices with regards to their cord bonding methods and gear.

Aluminum Wire Bonding: Methods and Applications

What is Wire Bonding?

Wire bonding refers to a greatly used interconnect approach that creates electric connections among microelectronic contraptions and their substrates. The process includes via skinny wires—regularly made from gold, aluminum, or copper—to set up these connections. It performs a a must-have role in semiconductor packaging and is foremost for guaranteeing that electronic devices objective with no trouble.

Understanding the Wire Bonding Process

The twine bonding course of could be damaged down into a couple of key steps:

Types of Wire Bonding Techniques

When it comes to twine bonding processes, a few strategies stand out:

- Ball Bonding: Utilizes a small ball at the quit of the wire created by way of heating it; most excellent for satisfactory-pitch packages.

- Wedge Bonding: Employs a wedge-fashioned device to create bonds; splendid for thicker wires.

- Ribbon Bonding: Involves the usage of flat ribbon-like wires for excessive-density purposes.

Each approach has its designated blessings depending on mission requisites.

Wire Bonding Equipment Overview

Wire Bonding Machines

Wire bonding machines are really good machine designed to automate the twine bonding technique. Key aspects frequently consist of programmable settings for diversified parameters which includes temperature and rigidity.

Manual vs Automatic Wire Bonding Machines

While handbook machines supply flexibility and keep watch over over small batches, automatic machines offer effectivity for excessive-volume production. The option in large part relies upon on creation wants.

Applications of Aluminum Wire Bonding in Electronics

Aluminum twine bonding finds good sized functions in alternative sectors:

- Semiconductors: Essential for connecting included circuits (ICs) on silicon wafers.

- Automotive Electronics: Used in sensors and management instruments because of its reliability less than varying situations.

- Medical Devices: Critical for guaranteeing longevity in existence-saving kit.

These applications reveal aluminum's versatility in assembly up to date digital demands.

Aluminum vs Gold Wire Bonding

When it involves comparing aluminum wire bonding with gold wire bonding:

| Feature | Aluminum Wire Bonding | Gold Wire Bonding | |--------------------------|-----------------------|--------------------| | Cost | Lower | Higher | | Oxidation Resistance | Moderate | Excellent | | Thermal Conductivity | Good | Excellent | | Usage | High amount | Specialty |

Aluminum offers price-effectiveness even as gold grants most efficient overall performance in phrases of oxidation resistance.

Challenges in Aluminum Wire Bonding

Despite its merits, aluminum twine bonding grants challenges:

Addressing these Go to this website demanding situations is critical for preserving reliability in electronic materials.

Wire Bonding Failure Analysis

Failure prognosis in wire bonding comprises reading defective bonds to make certain their root motives—be it illness or incorrect handling all the way through creation.

Wire Bond Reliability Testing Methods

To ensure bond reliability, producers hire a variety of checking out approaches:

These exams are fundamental for good quality insurance.

Future Trends in Aluminum Wire Bonding Technology

As expertise evolves, so does aluminum cord bonding:

- Innovative Materials: Research into new alloys may embellish efficiency and decrease fees further.

- Automation Advances: Enhanced automation will streamline techniques while convalescing precision.

- Miniaturization: As gadgets get smaller, strategies will proceed evolving closer to finer pitches and tighter tolerances.

This steady evolution guarantees that aluminum is still significant amidst changing technological landscapes.

Conclusion

In precis, aluminum cord bonding performs an vital function in cutting-edge electronics production simply by its distinctive ways and extensive-ranging applications. Understanding its techniques—from kinds of procedures employed to demanding situations faced—helps engineers and producers alike to harness its full skill accurately.

FAQs

1. What are the key kinds of components utilized in twine bonding?

The established substances used are gold, aluminum, copper, and silver simply by their conductive residences and differing prices linked to every textile %%!%%b13e7619-third-416d-8bd7-0401a711c3f5%%!%%.

2. How does thermosonic ball bonding vary from other tricks?

Thermosonic ball bonding combines warm with ultrasonic vitality all over bond formation; this contrasts with in basic terms mechanical or thermal systems determined in different suggestions which include wedge or ribbon bonding.

three. What components have an impact on bond reliability?

Factors comprise environmental conditions (like humidity), materials homes (which includes oxidation resistance), bond pad layout (dimension/tolerance), and properly appliance calibration all the way through construction runs.

4. Can I automate my present handbook twine-bond tactics?

Yes! Transitioning from guide processes most of the time calls for investing in programmable automatic machines that could considerably boom throughput even though chopping errors related to human handling.

five. What inspections may still be completed publish-wire bonding?

Common inspections include visible tests (for transparent defects), pull/shear checking out (to evaluate bond capability), x-ray inspections (for internal points), along environmental trying out if important primarily based on software necessities.

6. How do I choose between gold vs aluminum for my software?

Consider reasons like expense constraints versus overall performance demands; if oxidation resistance isn’t integral but budget constraints exist—aluminum might suffice—while gold suits excessive-functionality situations requiring top-rated reliability.

This accomplished discussion on "Aluminum Wire Bonding: Methods and Applications" serves as equally a information and reference aspect for these trying to deepen their information of this major technology within electronics production this day!