A Deep Dive into Wire Bonding Machines and Equipment

Introduction

In the fast-paced international of electronics production, the importance of powerful interconnection methods cannot be overstated. Among these, wire bonding emerges as a cornerstone technological know-how. This article targets to deliver a comprehensive analysis of twine bonding machines and kit, delving into more than a few facets comparable to approaches, applied sciences, programs, functions, and long term tendencies inside the trade. Understanding wire bonding is major for engineers and producers alike in attaining reliability and great in electronic instruments.

What is Wire Bonding?

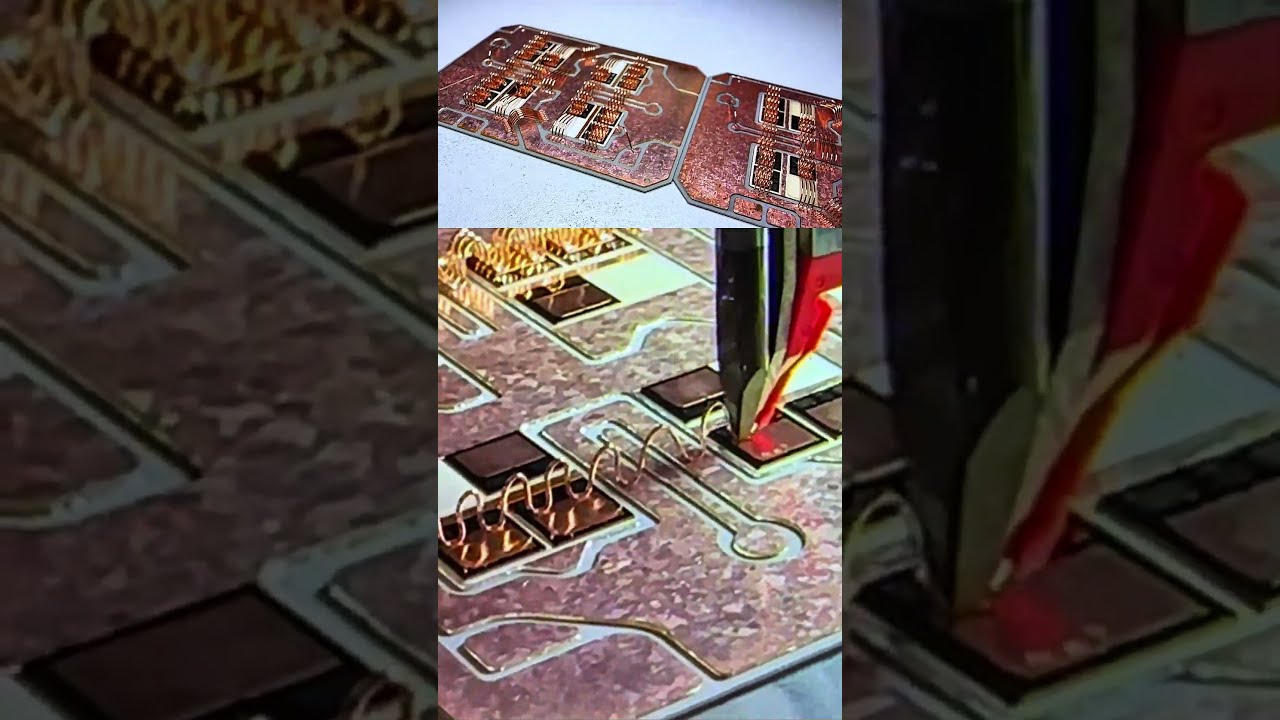

Wire bonding is a technique used to create electric connections among semiconductor chips and their programs or substrates. It entails by means of effective wires—customarily made of gold, aluminum, copper, or silver—to establish these connections. The job shall be performed simply by a good number of tactics reminiscent of ball bonding, wedge bonding, and ribbon bonding.

The Wire Bonding Process

The cord bonding task commonly comprises a couple of key steps:

This elaborate process guarantees risk-free connections which can be necessary for the performance of electronic devices.

Types of Wire Bonding Techniques

Wire bonding generation has evolved through the years, ensuing in more than one suggestions appropriate for numerous programs:

Ball Bonding

Ball bonding is one of the vital such a lot established techniques, mostly using gold or copper wires. In this approach:

- A ball is fashioned on the conclusion of the twine applying warmness.

- The ball is then pressed onto the bond pad to kind a connection.

Wedge Bonding

Wedge bonding employs a flat instrument other than a ball to make contact with either surfaces. This method is truly favourable for:

- Aluminum wires

- Applications requiring scale down temperatures

Ribbon Bonding

Ribbon bonding makes use of flat ribbons as opposed to au ball wire bonding spherical wires, making an allowance for top current capacities and diminished inductance. It's characteristically utilized in continual modules and prime-frequency packages.

Wire Bonding Machines: An Overview

What Are Wire Bonding Machines?

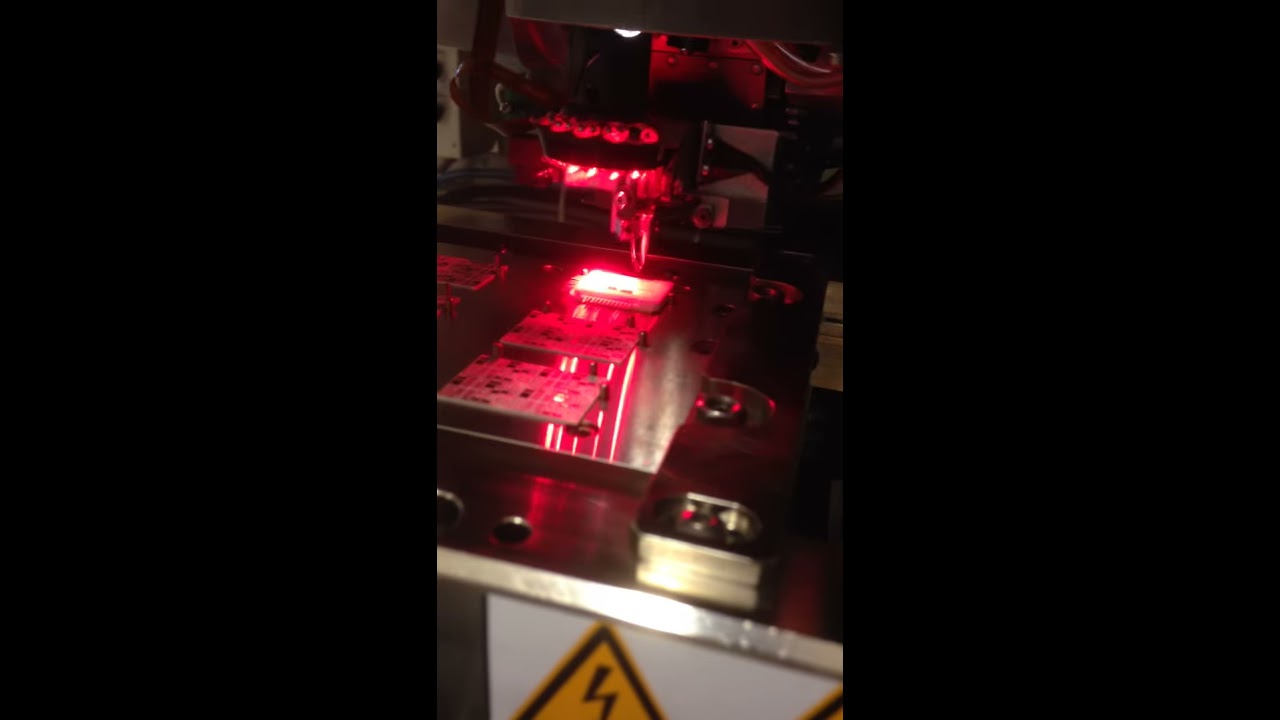

Wire bonding machines are specialised accessories designed to automate the wire bonding task. They come in a range of bureaucracy which includes guide, semi-automated, and absolutely automatic machines.

Features of Modern Wire Bonding Equipment

Modern twine bonding procedures offer a lot of options aimed toward rising potency and guaranteeing effective bonds:

- Programmable settings

- Advanced tracking systems

- Automated inspection tools

These elements help streamline creation whereas retaining stringent excellent manage requisites.

How Wire Bonding Works: A Technical Insight

Understanding how twine bonding works comes to greedy either mechanical and thermal points:

Bond Strength in Wire Bonding

Bond force is critical for reliability in electronic units; it's going to be prompted by explanations corresponding to:

- Material resolution (gold vs aluminum)

- Environmental conditions

- Process parameters (temperature and power)

Measuring bond strength incessantly includes pull tests or shear checks designed to guage the integrity of connections.

Wire Bonding Applications Across Industries

Wire bonding reveals its software throughout distinctive sectors owing to its adaptability:

1. Wire Bonding in Semiconductors

The semiconductor enterprise depends heavily on wire bonding for connecting included circuits (ICs) to programs or substrates without difficulty.

2. Wire Bonding for Medical Devices

Medical gadgets require top-reliability connections; for that reason many utilize stepped forward wire bonding innovations like superb pitch ball bonding.

3. Automotive Electronics Wire Bonding

As vehicles develop into more complicated with electronics, legitimate interconnections via cord bonds are valuable for security procedures and infotainment elements.

The Economics of Wire Bonding: Cost Considerations

Understanding the rate implications linked to alternative twine bonding equipment can help manufacturers optimize their operations:

1. Initial Investment vs Long-term Costs

While automated machines have a higher upfront money, they typically induce cut labor bills over time using increased throughput.

2. Material Costs: Gold vs Aluminum vs Copper Wires

Gold wires are more pricey than aluminum but provide most efficient performance beneath sure conditions (e.g., top-frequency applications).

Quality Control in Wire Bonding Processes

Ensuring caliber throughout production processes can keep defects that bring about failure modes in a while:

1. Visual Inspection Techniques

Visual inspection is still one of the crucial so much truthful tricks for finding out workable points early on along with bond elevate-off or heel cracks.

2. Non-damaging Testing Methods

Techniques corresponding to x-ray inspection or computerized optical inspection (AOI) enable producers to evaluate bond integrity without damaging aspects.

Wire Bond Failure Analysis: Understanding Defects

Fail-nontoxic layout calls for figuring out how disasters show up within bonded platforms:

Common Types of Wire Bond Failures

| Failure Mode | Description | |---------------------|-----------------------------------------------| | Heel Cracks | Cracks at the bottom of the bond | | Lift-Off | Complete detachment from bond pad | | Oxidation | Deterioration on account of environmental publicity |

Understanding these failure modes enables inform more desirable design practices and maintenance schedules.

FAQs

1. What resources are most of the time used for twine bonds?

Gold, aluminum, copper, and silver are ordinary material used for twine bonds by reason of their conductive homes.

2. How does temperature have an affect on the twine bonding course of?

Temperature performs a superb role; greater temperatures can raise bond force but might also bring about materials degradation if no longer controlled nicely.

three. What industries predominantly use cord bonding technology?

Industries incorporate semiconductors, car electronics, medical instruments, aerospace engineering, telecommunications, and the like.

4. How can I examine more about cord bonding tactics?

Numerous supplies exist online such as tutorials readily available in PDF format or academic videos that grant visual demonstrations of techniques in touch in wire binding.

five. What are some effortless demanding situations confronted all the way through wiring procedures?

Challenges embody dealing with thermal expansion modifications between elements used or stopping oxidation sooner than making connections which can compromise integrity.

Conclusion

In conclusion, knowing "A Deep Dive into Wire Bonding Machines and Equipment" reveals its crucial function throughout diverse industries—from semiconductors to automobile electronics—wherein legit interconnections style the spine of modern know-how progression efforts at the present time! By mastering either usual procedures like ball/wedge/ribbon ways which includes new improvements rising from improvements inside of Industry 4.zero frameworks—manufacturers stand poised no longer simply conveniently live on but thrive amidst ever-increasing competitors panorama ahead!

With understanding received for the duration of this exploration—whether or not you might be an engineer looking for purposeful insights into implementing high quality methods inside your possess operations—or honestly curious approximately modern-day advancements shaping long run landscapes—count that thorough comprehension leads in the long run against improved productivity & fulfillment within any field concerning not easy electronic strategies!